Your Cart is Empty

Have an account?

Log in to checkout faster.

You may also like

Great Summertime Kit Deals:

Understanding Router Feed Direction

Feed Direction For Freehand Routing

When you’re holding the router in hand with the bit facing downward, it will spin in a clockwise direction. To feed against the bit’s rotation then, you’ll move the router from right to left when feeding the router along the outside edges of a work- piece. If you’re routing all the way around a board, feeding right to left creates a counterclockwise motion — exactly what you want to do. You’ll feel an even and controllable resistance from the tool as the router bites into the wood.

Sometimes when freehand routing, you’ll need to rout around the inside edges of a cutaway area. Imagine routing around the inner cutout of a donut. In these situations, the feed direction changes. In order to move the router against the bit’s rotation on an inside edge, you’ll feed the tool clockwise — not counterclockwise. It’s the mirror opposite of routing outside edges, but the guiding principle stays the same: feed against the bit’s rotation for optimal control and cutting performance.

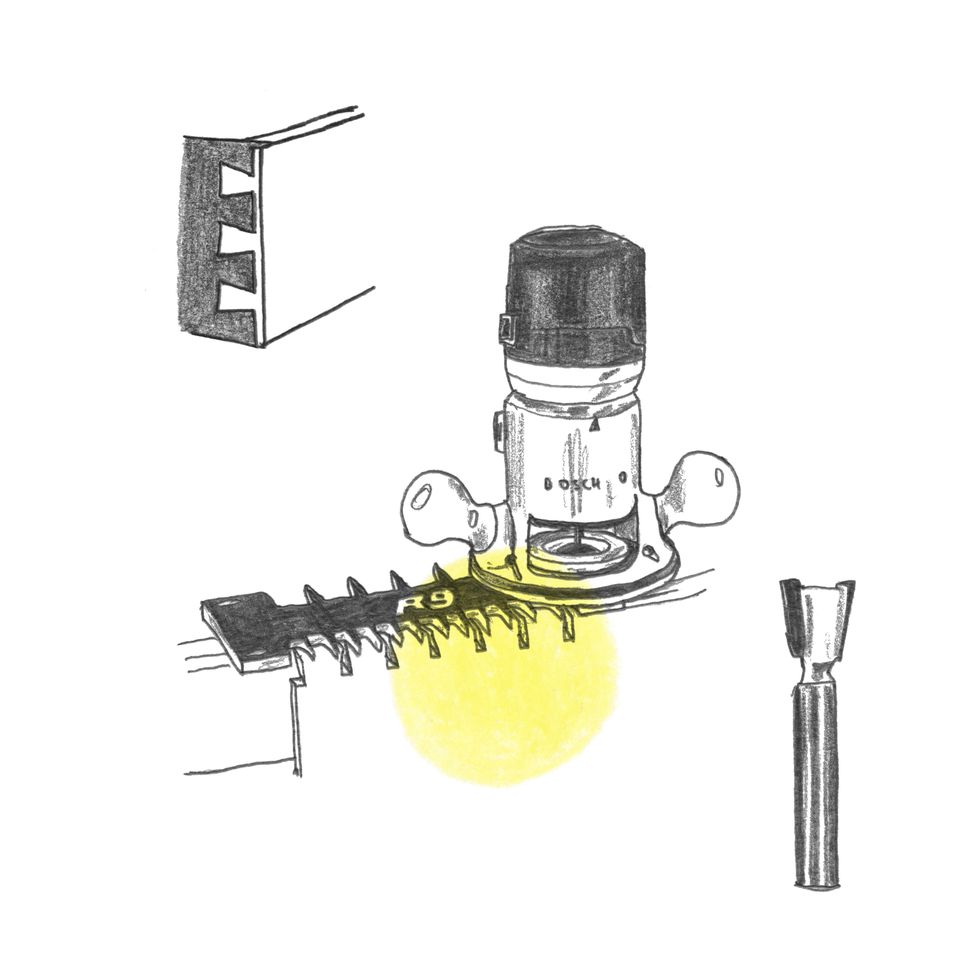

When routing by hand , the proper feed direction for inside cutouts (left) is clockwise. Feed the router counterclockwise for routing the outer edges.

Inverting a router in a router table changes the feed direction from handheld routing. For inside cutouts, feed the workpiece counterclockwise.

Feed Direction For Router Tables

Working on a router table means flipping the router upside down- and this reverses the bit’s spin direction. So, feed direction reverses also. On a router table, bits spin counterclockwise. For routing the outside edges of a work- piece then, you’ll feed the wood from the right side of the table to the left side. Doing this forces the bit to push the wood back against you. When the router fence is attached, the router bit will also press the wood against the fence. You want to maintain this resistance against the bit to keep the cut under control. The resistance you feel from the bit also helps you determine the right amount of force to apply and how fast you can move the wood past the bit to create a clean cut.

The normal feed direction on a router table for making outside cuts is to feed the work piece from the left to the right.

A safety issue you’ll face every time you turn on a router is which direction to feed the tool over the wood or the wood over the tool. In most situations, you want to feed the router into the wood against the rotation of the bit. Doing this will present the wood to the bit’s cutting surfaces so they bite into it but can’t pull it along. Feeding against the bit’s rotation will have the effect of pulling the router and wood tightly together and make the operation more predictable for you.

When working around the inside edges of a cutout on a router table, feed the workpiece counterclockwise, against the bit’s rotation. Again, you should feel an even amount of resistance from the forces created by pressing the wood against the bit’s cutting edges and direction of spin.

Climb Cutting

Working against the bit’s rotation, as outlined above, is always the safest and recommended approach to use, regardless of the routing situation. Sometimes, however, the wood you’re routing will have uneven or difficult grain that doesn’t rout smoothly. Working against the bit’s rotation will cause the bit to tear out fibers in the wood; that leaves a rough and unacceptable surface. When this happens, one option to improve the routed surface is to set the router for a slightly deeper pass and move the router with the bit’s rotation instead of against it. This practice is called climb cutting, because feeding with the bit’s rotation will make the router want to climb out of the cut instead of digging into it. Instead of feeling the effect of resistance against the bit, the router will want to grab the wood and pull away from you when climb cutting. So, the router is harder to control and less predictable.

Climb cutting is a somewhat controversial technique for routing. It must be done cautiously, with workpieces safely clamped in place or with the router anchored in a router table. For more on how to make a climb cut, see Chapters Six and Seven.

This article is excerpted from "The Complete New Router book for Woodworkers". ©2006 Handyman Club of America.

Related Categories

Power tools & accessories, dimensional lumber, hand sanding tools.

- Choosing a selection results in a full page refresh.

Favorite Your Store

Form field Zip or City is required. Please fill out the value.

Favorite Store

Hours of Operations

Free Shipping On U.S. Orders Over $100 | 10% Off Entire Order On International Orders Over $300

- Bits & Bits Company

- CMT Orange Tools

- Hongdui Tools

- Jay's Custom Creations

- Katz-Moses Tools

- Rubio Monocoat

- Suizan Japanese Saws

- Dovetail & Joinery Tools

- Forged Hand Tools

- KM Tools Templates

- Measuring & Marking

- Router Bits and Forstner Bits

- Safety and PPE

- Sanding and Finishing

- Saw Blades and Table Saw Accessories

- Walnut Slabs

- Best Sellers

New Arrivals

Build Plans

- Build Up Initiative Plans

- Digital Content

- KM Tools Apparel

Woodworking Classes

- About KM Tools

Creator of the Week

- Katz-Moses Woodworkers with Disabilities Fund

- Partner With Us

- Free Router Table Plans

- Five Cut Method Calculator

- Linear Board Foot Calculator

- Wood Movement Calculator

Cookie policy

I agree to the processing of my data in accordance with the conditions set out in the Privacy Policy.

Your cart is empty

2 Easy Ways to Remember Router Feed Direction (Quick Tip)

One of the most important aspects of router safety is getting feed direction right.

That means being aware of how you make cuts relative to the router bit’s rotation.

Essentially, you want the direction you push the router along the edge of a board to be the opposite of the bit’s rotational direction .

Cutting in the same direction as a bit’s rotation is called a climb cut — and if you’re not careful, it can cause the router to shoot out of your hands… or send the board you’re cutting shooting across the shop.

Overtime, cutting direction becomes second nature.

But when you’re first getting started, it can be a bit confusing (punny, I know). Especially if you’re switching between a handheld router and router table.

To make it easier, I’m sharing 2 easy tricks to help you remember router feed direction — until safety becomes second nature.

1. THE RIGHT HAND TRICK

When you’re first getting started, this trick is the easiest way to quickly remind yourself of the correct feed direction.

It uses your right hand — with your fingers and thumb representing different elements of the router.

Start by making a “thumbs up” sign with your right hand.

Your thumb represents the orientation of the router bit. So if you’re using a router table, point your thumb up. If you’re using a handheld router, point your thumb down.

The direction your fingers curve represents the router bit’s rotation. So whichever way they’re pointing is how the bit spins in that orientation.

(You’ll notice that for handheld routers the bit spins clockwise, and on router tables it spins counterclockwise).

Your feed direction should be the opposite of whatever direction your fingers are pointing.

So whether you're pushing a handheld router — or pushing a board over a router table — the direction that the board’s edge moves along the bit should be the opposite of that bit’s rotation.

For example, say you’re cutting a rabbet in a board with a handheld router. Make a “thumbs down” sign next to the edge you’re cutting and look at where your fingers point.

Push the router the opposite way through the cut — and you’ll have all the control you need!

2. THE PICTURE FRAME CLOCK

This method isn’t as intuitive as the right hand trick, but can still be a good frame of reference (dang it, another pun).

Imagine you’re rounding over the edges of a picture frame.

For a handheld router , you want to push the router:

- Counter clockwise on the outside edge of the frame

- Clockwise on the inside edge of the frame

On a router table, you can think of the same directions — but now you're moving the workpiece instead of the bit.

So on a router table you’d rotate the workpiece :

- Counter clockwise for the outside edge of the frame

- Clockwise for inside the inside edge of the frame

The clockwise/counter clockwise idea remains the same. What changes is whether you're rotating the router or the actual board .

Just remember:

- Outside edge = Counter clockwise

- Inside edge = Clockwise

For handheld routers that rotation refers to the actual router, while on router tables that rotation refers to the workpiece.

Cutting with the correct feed direction will give you greater control with your router — keeping you safe as you build.

And with the two tricks above, you’ll have no problem remembering… until you get enough experience to just know.

Want more router safety tips? Read this.

Got your own trick for remembering feed direction? Let us know in the comments below!

Follow us on Instagram @katzmosestools , on TikTok @katzmoseswoodworking , and check out my YouTube channel for more great woodworking content...

And as always, STAY SAFE IN THE SHOP!

Continue reading

6 Tips for Starting Hand Saw Cuts (Quick Tip)

How to Flatten Slabs and Wide Boards with a Router Jig

I’ve been struggling with my router for years. This was a very good explanation. Totally helpful! Thank you.

David Meadow

I use the left to right method. When facing the piece, cut from left to right. Doesn’t matter if you are holding the router or it’s in a table.

Thanks JKM, another great article. The “right hand trick” I learned for handheld routers is; make an “L” with your right thumb and index finger like a kid makes an imaginary pistol. Then with your palm facing down touch your thumb to the edge you want to rout. Your finger points the way of the router. Works for inside and outside edges. We used the “thumbs up” for a reminder of bit rotation on the router table.

I had trouble routing a wide blind slot (both ends blind) – I hog out as much as possible with a forstner bit – drilling each end of the slot oversized to drop the piece over the router bit – then cut each side – problem is should I cut the between the bit and fence or the side opposite of the fence?

Maybe I need to glue up two pieces of wood with spacer blocks then plane, joint and cut to size…

Tom Albertson

Food for thought: if you change the “right hand trick” to the “left hand trick” then your fingers would point in the feed direction. Maybe easier to remember if you want to know which way to push the router/work piece and don’t care which way the bit spins. (No, I’m not left handed.) In any case, this info is great! Thanks!

Jim A. Paschis

The picture from interior and exterior surfaces present a good example for router feed directions. When advancing toward the next 90 degree piece with the exterior edge extremely thin there is a chance for corner tear out. For crucial, delicate work a protective piece can be clamped and routed.

Joseph Lowe

EXCELLENT! This really should not be difficult, and it’s embarrassing how many times I’ve had to figure this out moving between routers, particularly if I haven’t routed in a couple of weeks. Many thanks.

Leave a comment

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Subscribe to the KM Tools Newsletter

Sign up and receive free build plans for the Katz-Moses Router Table as well as exclusive access to:

- Early notifications for upcoming product launches

- Sales and discounts on our most popular products

- Weekly educational woodworking content

What Router Direction Should You Use (Clearly Explained)

The router direction can make a big difference between nice, smooth cuts or dangerous cuts with an increased risk of accidents and uneven and untidy edges. But what is the correct router cutting direction?

The correct router direction is always in the opposite direction of the rotating router bit. When you know that a router bit always turns clockwise, you will understand that you have to push the router in the opposite direction.

In this article, you will get a good idea of which direction to use a router , depending on whether you are using a handheld router or router table. In addition, there are some router cutting direction exceptions, which you will understand after reading all the useful information you can find below.

Disclosure: At zero cost to you, I may get commissions for purchases made through links in this post. I earn from qualifying purchases as an Amazon associate. Products featured are selected based on quality, performance, and reputation, regardless of affiliate relationships.

What happens when using the wrong Router Direction

If you use the wrong handheld router direction or the wrong feed on the router table, the routerbit will push itself away from the wood you want to work . Due to the high router bit speed , this will make the router difficult to handle and make sudden uncontrollable movements that can be very powerful.

When using a handheld router, the router can be pulled out of your hands and the router bit can cause injuries. With a router table, the material will be pulled out of your hands or your hands will pull towards the router bit.

Whatever you use, hand router or router table, feeding the wood incorrectly can cause serious injury . In the least bad situation, you will end up with an uneven and messy-looking edge.

When working with cutting tools, there is always a risk of injury. Be well-prepared and set up a first aid kit in your workshop. You can read how to do this in my article How To Make A Workshop First Aid Kit – N°1 Guide | FREE CHECKLIST

Understanding Router Direction

To know which direction to use a router bit into the wood (hand router) or the correct input of the wood into the router bit (router table) , you must first know in which direction the router bit will rotate.

The correct router cutting direction is always against the direction of rotation of the router bit. This way, the router bit will cut into the wood (conventional cut) instead of pushing the wood away (climb cut). I’ll go into this in more detail in a moment.

In a handheld router, the router bit rotates clockwise, so if you have to enter it in the right way, the feed direction is usually from left to right. Please note , there are exceptions to this rule, which I will discuss further in this article.

When using a router in a table or mounted on a worktop, the direction of rotation of the bit changes. By mounting the router upside down , the router bit now rotates counterclockwise. As a result, the feed direction will often be right to left.

What is a conventional cut

The most secure cut is the conventional cut. The feed is in the opposite direction as the rotating cutter. In other words, a conventional cut is made by turning the router bit clockwise and pushing the router from left to right.

What is a climb cut

The climb cut is the opposite of the conventional cut. The wood is fed in the same direction as the rotary router bit. So when the router bit is turned clockwise, and you move the router from right to left, you make a climb cut.

The climb cut is therefore the unsafe way to work with the router. Because the router moves in the same direction as the rotating router bit, it will tend to push itself away from the wood instead of cutting into it. Due to the shedding, the router bit will therefore move away from the wood and thus make a “climbing” movement, hence the name climb cut.

Different router feed directions for handheld routers

From all the information you could already read, you now know that when milling along an outer edge with a hand mill , you always have to work from left to right, against the rotation of the mill (conventional cut).

This is the safest way to work with a handheld router and will result in a smoother cut.

However, there are sometimes exceptions to this rule. For example , if there is a chance that wood will break out on the corner, it can be good to make a short climb cut to prevent this. After that, you can continue with the conventional cut.

There are other situations where the push direction of the router is different. Below I will explain all possible router directions briefly and clearly.

Routing along the outer edge

This is the most common situation you will face. When you have a workpiece that you need to mill the outside of, always move the router counterclockwise.

Routing inner edges

Here you have to think the other way around. Remember that the bit always turns clockwise, so you have to push the router in the opposite direction.

When milling along the inside edges of a piece of material, you should work in a clockwise direction. this will allow the router bit to cut into the wood.

Routing a circle or arc

Although the circle has a different shape than a square workpiece, the method is the same. When milling an arc or circle with a handheld router, always move counterclockwise.

Routing a groove through the material.

When milling a groove through the center of a workpiece, there will always be material on both sides of the cutter. So you will wonder what the correct router direction is for this.

Well, if you’re cutting a freehand groove there’s really no right answer to this question. Any direction you use is the correct push direction since the router always has one side that moves with its rotation and one side that moves against its own rotation at the same time.

However, do not try to change the feed direction abruptly at any time, as this may cause the router bit to unexpectedly engage the wood and make uncontrollable movements.

However, if you are using a guide/side stop it is a good idea to choose the direction where the router bit always pulls the router towards the guide, thus avoiding climb cuts where the guide comes loose from the wood.

Different router feed directions for router tables

Routing an outer edge.

When milling an outer edge with a stationary router, you must feed the material from right to left, as you could read earlier in this article.

Making a reverse feed motion is dangerous and increases the risk that the bit will pull the material out of your hands and your hands may come into contact with the router bit.

Route a groove through wood

As with milling a groove with the hand mill through the center of a workpiece, the router table will always have material on both sides of the mill.

So the correct direction for milling a groove with the router table is the direction where the bit always pulls the wood against the fence . This way you avoid the wood being pushed away from the fence by a climb cut.

The router bit rotates clockwise at all times. All you have to do is run the router counterclockwise to cut into the wood . This allows you to make the safest cuts while also ensuring that the cut is always nice and smooth.

If you want to learn more about how to get the most out of your router , I recommend reading my article, How To Use A Router – Easy 5-Minute Starter Guide .

How to build your workshop on a budget?

Building your workshop can be daunting, filled with trial and error. Believe me, I’ve been there too. But it was “The Ultimate Small Workshop” course, a gem I discovered and now endorse on Christofix.com , that provided insights unparalleled to any other. This expertise empowered me to invest wisely and save substantially.

I really suggest it to all of my fellow DIYers and creators!

I hope this information about the correct router direction was helpful, and that this blog inspires you. Feel free to share this blog on Facebook, Pinterest, or other social media . You can do this by using the buttons below or at the top of the blog. It will be much appreciated. I’m looking forward to seeing you soon in another blog or video. Greetings, Christophe, founder of Christofix.com Woodworking | DIY | Home decoration

Meet Christophe - Founder & Woodwork Artisan Behind Christofix.com

Hi, I'm Christophe. With a daily dedication to woodworking, my expertise has grown immensely since starting in a modest garage in 2018. Today, I'm a recognized figure in the woodworking community, sharing daily insights and techniques at Christofix.com for enthusiasts at all levels, emphasizing sustainable and artistic woodworking.

Home Articles Basic Links Projects Reference Tips & Tricks Tool Reviews Video Woodturning Contact About Us

This is a Veteran Owned site

Confusion is easy!

Text and photos by Tom Hintz

Considering that the router is one of the most popular woodworking tools, it is no surprise that questions regarding its use are common. Of nearly 300 email questions in my "hold" folder, 188 of them related to basic router use. What is especially interesting is that the majority of these questions involve feed direction and rates, both of which are crucial to safety and the quality of the cut.

Feed Direction and Danger

The good news about feed direction is that with very few exceptions, the stock always moves against the rotation of the bit. The bad news is that making a mistake with feed direction can easily initiate a very dangerous kick out with little or no warning.

Feeding the material against the rotation of the cutter affords control because the cutting action creates resistance to the force being applied by the operator to move the wood across the bit. This balance of forces makes controlling the wood much easier.

If the wood is introduced in the same direction as the bit is rotating the cutting edges instantly become extraordinarily efficient high-speed power feeders that can suddenly eject the wood, leaving the operators empty hands dangerously close to the cutter. This situation is particularly dangerous because the force the operator was applying to the wood before it kicked out immediately causes the now empty hands to lurch toward the bit. Disaster can be the instantaneous result.

Confusion Is Easy

It is apparent that the most frequent cause of feed direction errors is operator confusion regarding which side of the cutter, in relation to the operator, is turning which way. The router is the only commonly used wood working power tool that can be used with the cutter facing up in table-mounted situations, or down for hand-held operations. When router orientation is changed from bit up to bit down modes, the operator has to remember that feed directions change as well.

For clarity in this story, the "rear" of the bit is the cutting edge farthest from the operator and the "front" refers to the edge closest to you.

Consistent Practices

The easiest way to reduce feed direction errors is to develop standard operating procedures used each time a task is performed. Taking the time to double check the feed direction before each operation is a very good habit to get into.

Hand-Held Operations

I always start at the lower left corner of the piece when cutting the outside edge in the hand-held mode. The bit is spinning in a clockwise direction from my perspective so engaging the rear of the bit with the wood means the router always moves left to right and goes around the remaining sides of the piece in a counter clockwise direction.

When routing an inside edge, like when cutting the inside edge of a frame or opening, I start at the upper left corner so the rear of the bit again engages the wood and the router moves left to right. The only difference is that when cutting the inside edge, continuing the left to right motion takes the router around the opening in a clockwise direction.

Using the same starting point every time develops a habit that goes a long way towards preventing directional errors and the damage and danger that can create.

The exception to this would be when therre are end grain sections that are to be routed. Generally, we route the end grain segments first, and then the rest of the piece so any chipping that occurs at the end grain is removed in the final passes. I usually do the end grain first, then start at my normal position and go all the way around the piece, including a second pass over the end grain segments, so I get nice clean transitions from one side to the other.

Router Table Operations

safety note: whenever routing pieces on a router table be sure to use proper push stick, pads or other safety equipment that keep your hands a safe distance from the cutter..

When the router is installed bit-end up in a router table, bit rotation from the operators perspective is counter-clockwise. When using a fence or miter guide, the edge of the cutter closest to the operator is used and the material is fed right to left.

An exception is when cutting a centered slot in a piece of wood. The first pass is made by holding the wood against the fence and then plunging it down over the bit at the start point and then feeding the stock into the cutter from right to left. However, when the piece is reversed to make the second pass to center the slot, the rear edge of the bit is often doing the cutting. In this case, the piece has to be fed from left to right.

When making this type of cut, I have found it safest to make the first pass (right to left) and then shut off the router. I reverse the work piece and hold it in position above the router bit to make sure which edge of the bit will be doing the cutting. If the rear edge of the bit is doing the cutting, the work piece has to be fed across it from left to right.

It should be noted that cutting centered slots on a router table is always a difficult and somewhat dangerous operation. If you are at all unsure of your skills or safety equipment, make the slot by drilling holes at either end and then removing the material between them with a jig saw.

Occasionally router bits equipped with bearings are used in the router table without the fence. We have to remember that the router bit rotation is counter clockwise and adjust feed directions accordingly. When the front edge of the bit is used, the stock is fed right to left. If the rear of the bit is engaged, feed direction is left to right.

Remember to use the proper push sticks or pads to keep your hands far away from the bit. Without the fence, the bit will be totally exposed if the wood kicks out or breaks.

Climb Cutting

There are two situations when climb cutting, moving the router in the same direction as the bit rotation is acceptable. Climb cutting is always difficult and care must be taken to maintain control of the router.

The most common climb cut is on a dovetail jig with the router in the hand-held position. A small portion of the cutters edge is used to make a very light scoring cut, moving from right to left, to reduce tear out. Even though very little of the bit is engaged in the wood, care must be taken to maintain control of the router as it could want to accelerate down the wood.

The other situation when climb cutting is used is when using some laminate trimmers. Feeding the router against the bit rotation sometimes causes these materials to "chip" ahead of the cutter. In these cases, the laminate is trimmed as close to the base material as possible with other tools and then the router can be used to clean the edge, moving it in the same direction as the bit rotation.

Whenever climb cutting, whether on a dovetail jig or trimming laminates, keep the cuts very light and a firm grip on the router to avoid having it get away from you. Climb cutting without using proper procedures is very dangerous.

Determining the proper feed rate for any bit is relatively easy, assuming the router speed is set correctly for the bit. If the bit burns the wood, the feed rate is too slow. If the wood chips or blows out ahead of the bit, the feed rate is too fast. Granted these are generalizations and there are other factors that could contribute to these problems, but they remain important clues about what you may be doing wrong.

Feed rates and bit performance are directly related to the depth of cut. Trying to remove too much material in a single pass can cause or increase burning and blow out ahead of the bit. It is always better to make multiple light cuts than fewer deeper cuts. Lighter cuts are far safer and produce much better results.

The Bottom Line

Routers extremely useful in the workshop, but they can also be very dangerous if used improperly, including the failure to employ adequate safety equipment, procedures and feed direction.

If you find yourself faced with a router-related task that you do not completely understand or do not have the proper safety equipment for, the only prudent course of action is to stop! Wait until you get the information and equipment to make the operation safe. The task will be there later, your fingers may not.

As with all power tools, the major cause of accidents is operator error. Not taking the time to be certain of feed direction with a router is dangerous, and could lead to severe injury. There are many woodworkers who have learned to pursue this hobby with a disability caused by a moment of lost concentration. Take the time to make sure you do not join those ranks.

Other Router-Related Stories

Reading the Grain Using Rabbet Bits Setting Up Rail and Stile Bits

Do you have a comment about this page? - Email Me!

Back to the Tips & Tricks List

Subscribe Today!

Save up to 64% and get a free gift. Subscribe »

Which Way Does the Router Spin? – Tricks of the Trade

We may receive a commission when you use our affiliate links. However, this does not impact our recommendations.

I learned this in engineering school and soon found out it worked for my router. It is called the “right-hand thumb rule.”

When trying to remember which way your router bit is spinning so you can feed the wood in the correct direction, you can use the right-hand thumb rule.

Pretend your right hand is a router and your thumb is the router bit. If you are holding the router with your hands and the bit is pointing down to the floor, then hold your hand in front of you with your thumb pointing to the floor. Then curl your fingers. That’s the direction your router bit is spinning.

If you are using a router table, hold your hand with your thumb pointing to the sky. Curl your fingers, and that’s the direction your router bit is spinning.

That way you will never get confused again and always know the correct feed direction.

And it works for almost anything that spins: faucets, screws (regular thread), changing a tire (if you want to know which way to tighten or loosen the nuts) etc.

With Power Tool Essentials – Digital Collection you’ll learn:

About proper drill press speeds for different bits and how to set the pulleys to match. Tips for tilting & realigning the drill press table for accurate drilling. The simple steps to keep mortiser chisels and drill bits sharp and cutting true. How to set the mortiser bit and chisel perfectly to avoid heat build-up and improve chip removal. Ripping and cross-cutting tips for sheet goods and solid wood. How to improve cuts using the proper blades. Where to stand and how to position your hands and body for the safest, most accurate performance. Simple maintenance and accurate setup and much more!

Learn the ins and outs of power tools with this digital collection!

Here are some supplies and tools we find essential in our everyday work around the shop. We may receive a commission from sales referred by our links; however, we have carefully selected these products for their usefulness and quality.

1/2" Straight Bit

Table Saw Blade

Tape Measure

I get the router bit explanation. I don’t get the lug nut or any thread explanation though. Is your thumb supposed to be the exposed thread of a lug nut? If it is, then your fingers would’ve loosening. How about a faucet, what is your thumb supposed to be?

- How to Videos

- Customer Service

- Advertise/Media Kit

- Affiliate Program

- Become a Contributor

- Active Interest Media

Start typing and press Enter to search

The Right Way To Use a Router

Many woodworkers consider the router to be the most versatile portable power tool in the shop. Here's why.

Gear-obsessed editors choose every product we review. We may earn commission if you buy from a link. Why Trust Us?

We love the Bosch's beechwood knob handles. But more impressive is the whopper of a 2 ¼-hp motor that allows you to control its speed with the turn of a red thumbwheel. The Bosch doesn't roar. With a sharp carbide bit, that big motor just purrs as the router leaves a gleaming, crisply shaped edge in its wake. It's a wonderful thing to behold, and as power tools go, it's a classic that makes every amateur look good.

Move to the Right

The biggest mistake novice woodworkers make is advancing the router in the wrong direction. It's easier to practice the correct technique than it is to explain it, but here goes: First, always move the router against the rotation of the bit. That allows the bit to cut into the work, giving you full control over the tool. If you advance the router in the same direction as the bit's rotation, the router will run along the edge of the workpiece and you'll have to fight to keep control.

When looking straight down at the top of a router, the bit rotates in a clockwise direction. That means you should move the router from left to right, but—and this is important—that's only true when the router is positioned in the middle between you and the workpiece.

For example, if you were routing the edges of a board, you'd move the router from left to right across the edge closest to you. But, when routing the opposite edge, the one farthest away, you'd advance the router from right to left. That's because the workpiece--not the router--is now in the middle. In that position, the router is moving right to left, but it's correctly cutting against the rotation of the bit.

Be the Co-Pilot

One of the best and safest ways to begin routing is to use router bits fitted with ball-bearing pilots . The bearing rides along the edge of the workpiece, effectively keeping the bit on course and in control. Simply set the depth of cut and you're ready to rout. There's no need to attach an edge guide to the router or straightedge fence to the work. The bearing alone will ensure the bit cuts to the proper width. Nearly all edge-shaping and trimming bits are available with ball-bearing pilots, including rounding-over, Roman ogee, chamfer, rabbeting, and flush-trimming.

Take the Guided Tour

Once you've mastered basic routing techniques, create a precise milling machine by equipping your router with a guide bushing and straight-cutting bit . A guide bushing (aka template guide) is simply a steel collar that mounts onto the router's base. Protruding from the collar is a short steel tube through which the bit extends. The tube is guided along the edge of a template, allowing you to quickly cut boards to virtually any size or shape. Here's a brief description of how to use a guide bushing:

Start by cutting a template to the desired shape out of plywood, MDF or hardboard. When making a template, take into account the offset between the outside edge of the bushing and the cutting edge of the bit; a distance that's usually about 3/16 in. Also, be sure to sand the template edges perfectly smooth. Otherwise the bit will transfer any imperfections to the workpiece.

Clamp the template in place, then advance the router into the workpiece. Be sure to keep the guide bushing pressed tightly against the edge of the template. Guide bushings are useful for routing curved, irregular shapes, but also for precisely cutting hinges and mortises. You can buy guide bushings individually, but it's usually more economical to buy a multipiece set .

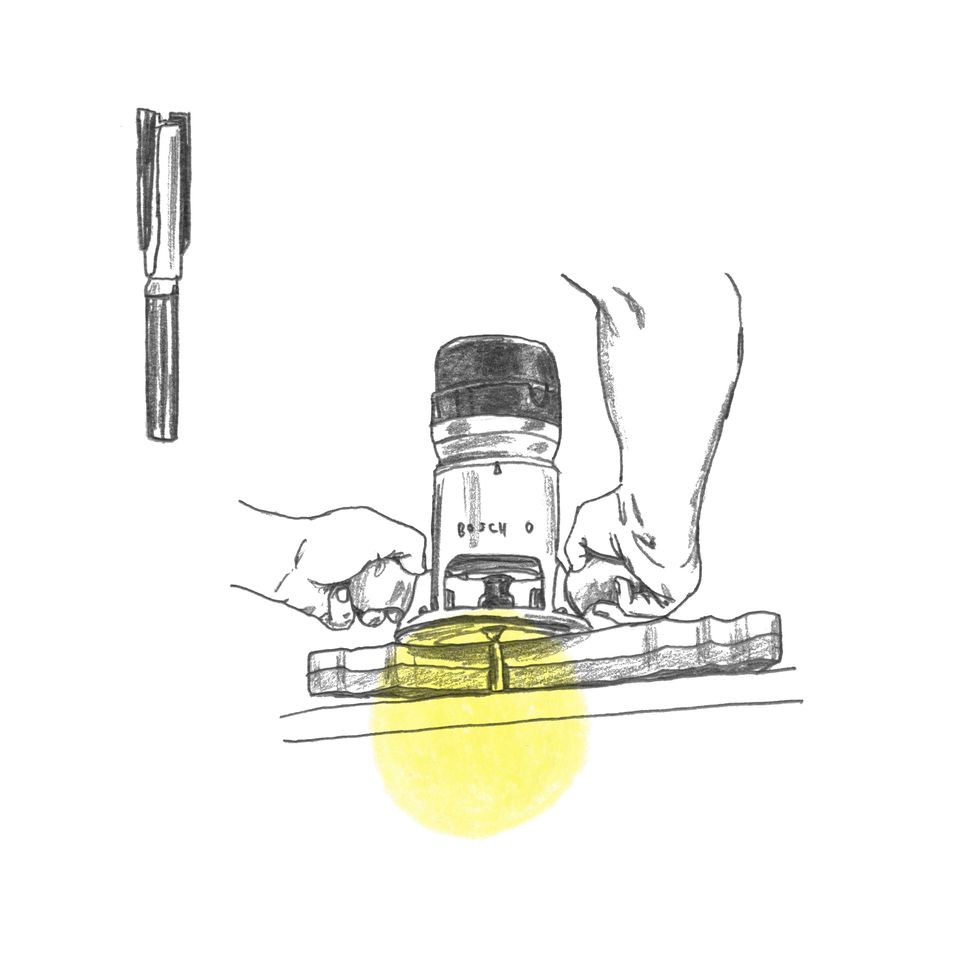

Turn it Upside Down

Mounting your router upside down in a router table greatly expands the tool's capabilities, making routing easier and safer. With the tool held securely in place, you can use both hands to safely feed the stock into the bit. And since the bit is clearly visible, you can see exactly what you're doing. (That's not always possible with handheld routing.) Router tables are especially useful when milling smaller parts, cutting stopped grooves, or using large-diameter bits. In fact there are some bits, including certain raised-panel bits, that should only be used in a router table.

You can make your own router table easily enough, and many table saws have extension wings that accept a router. But for most DIYers, a store-bought router table is the best option since it comes ready-to-use with all the necessary equipment, including an adjustable fence, miter gauge, On/Off switch, dust-collection port and bit guard. However, router tables typically don't come with a router, so check the specs before buying one to ensure your router fits the table.

Claim Your Door Prize

Building traditional frame-and-panel cabinet doors is virtually impossible without a router. The stiles and rails that form the door's frame are joined together with tight-fitting coping and sticking joints. The door's raised panel has beveled edges that fit into shallow grooves cut in the frame parts. The frame is assembled with glue only, so all the joints must be milled precisely for the parts to properly fit together. And the router is the tool to use to cut these joints. You'll also need a router table to safely make the cuts.

Rail-and-stile bits are sold in sets, and raised-panel bits are sold individually. You can also buy cabinetmaking sets , which include all three bits.

Dovetail Details

There are few wood joints as strong or as beautiful as a dovetail. Wedge-shaped pins fit snugly into dovetail-shaped tails, effectively locking the two boards together. Dovetail joints are commonly used to build drawers, blanket chests and jewelry boxes.

And while it is possible to cut dovetail joints by hand, using a router and dovetail template is precise and much faster. A dovetail template is essentially a vise that's equipped with adjustable metal fingers. You clamp the tail board into the template and then use a dovetail router bit to cut the tails. Next, install the pin board into the template and use a straight router bit to cut the pins. It's a little tricky getting all the pins and tails properly aligned initially, so make a few test cuts in scrap wood before routing the workpieces.

Four Ways to Rout

Straight groove.

Grooves appear everywhere in woodworking. For example, use one to seat a drawer bottom in drawer sides, front and back. To make a groove with a router, use a fence accessory. Set the fence the required distance from the bit and set the bit's depth. Not much more to it than that.

Dovetail Joint

Dovetailing with a router requires two things: a dovetail template and a corresponding bit. You perform two operations with the template. With one you cut the dovetail and the other you cut the pins. Push the two parts together with wood glue between them and you have a nearly unbreakable joint.

Routered Edge

A router can cut any decorative edge on a workpiece, from a simple rounded corner to a series of curves in a single pass with a Roman ogee bit. These shaping operations may be guided by a ball-bearing bit or a bit minus the bearing. With either method, take a test run on scrap before working on the actual piece.

Template Cut

The fastest way to make exact duplicates of a part, such as four bracket feet for a blanket chest, is to use a pattern and a top-bearing straight bit. The bearing rolls along the pattern as the straight bit carves the wood.

Joe Truini is a former carpenter and cabinetmaker who writes extensively about remodeling, woodworking, and tool techniques. He's the author of eight DIY books and is a long-time contributing editor to Popular Mechanics .

Roy Berendsohn has worked for more than 25 years at Popular Mechanics, where he has written on carpentry, masonry, painting, plumbing, electrical, woodworking, blacksmithing, welding, lawn care, chainsaw use, and outdoor power equipment. When he’s not working on his own house, he volunteers with Sovereign Grace Church doing home repair for families in rural, suburban and urban locations throughout central and southern New Jersey.

.css-cuqpxl:before{padding-right:0.3125rem;content:'//';display:inline;} Tools Reviews .css-xtujxj:before{padding-left:0.3125rem;content:'//';display:inline;}

The 9 Best Pole Saws for Every Tree-Pruning Job

The 4 Best Garbage Disposals, Tested

The Best Cordless Impact Wrenches

The 8 Best Battery Stringer Trimmers for Lawn Care

Amazon Warehouse Craftsman Tool Sale: Get 50% Off

The 9 Best String Trimmers of 2024

The Best Reciprocating Saws for Powerful Cuts

The Best Portable Table Saws

The 5 Best Zero-Turn Mowers of 2024

The Best Dust Collection Systems for Your Shop

The Best Electric Mowers of 2024 for Any Yard

IMAGES

VIDEO

COMMENTS

When routing by hand, the proper feed direction for inside cutouts (left) is clockwise. Feed the router counterclockwise for routing the outer edges. Inverting a router in a router table changes the feed direction from handheld routing. For inside cutouts, feed the workpiece counterclockwise.

1. THE RIGHT HAND TRICK. When you’re first getting started, this trick is the easiest way to quickly remind yourself of the correct feed direction. It uses your right hand — with your fingers and thumb representing different elements of the router. Start by making a “thumbs up” sign with your right hand.

The correct router cutting direction is always against the direction of rotation of the router bit. This way, the router bit will cut into the wood (conventional cut) instead of pushing the wood away (climb cut).

130K views 9 years ago Carpentry and Woodworking for Beginners. Leah from See Jane Drill demonstrates the most commonly recommended direction to push your router, also known as a push cut....

When using a router it is important to know the correct direction of feed. The following guidelines will help you to determine this. All episodes of the Router Workshop are available to watch online. This includes all 183 episodes which is over 75 hours of router & woodworking content.

A detailed tutorial about router feed direction and climb-cutting safely! EXPAND THIS SECTION FOR MORE RESOURCES RELATED TO THIS VIDEO *Tools used in thi...

The router is the only commonly used wood working power tool that can be used with the cutter facing up in table-mounted situations, or down for hand-held operations. When router orientation is changed from bit up to bit down modes, the operator has to remember that feed directions change as well.

Router Direction. Router direction is extremely important not only for the best results but also for safe operation. The router should be run opposite to the bit’s rotation. When the bit rotates, the cutting edge should meet the wood at the start of each rotation.

When trying to remember which way your router bit is spinning so you can feed the wood in the correct direction, you can use the right-hand thumb rule. Pretend your right hand is a router and your thumb is the router bit.

Many woodworkers consider the router to be the most versatile portable power tool in the shop. Here are six router tips divided by experience level.