Step inside Boeing's South Carolina Dreamliner factory

For most of its history, Boeing has been synonymous with the Seattle area. Although the global aerospace company has facilities across the U.S. and abroad, it was founded in Seattle, and for most of its history, it built its commercial aircraft at two Seattle-area factories.

In 2011, Boeing opened a third commercial factory, this one in Charleston, South Carolina.

The new location came to be after Boeing purchased the South Carolina-based operations of two suppliers in 2008 and 2009: Vought Aircraft Industries and Global Aeronautica, which built components for Boeing.

Boeing absorbed both operations and combined them, before opening a final 787 assembly and delivery line on the site two years later.

Want more airline-specific news? Sign up for TPG's free biweekly Aviation newsletter .

The Charleston site operates alongside Boeing's Everett factory in Washington state, which produces wide-body commercial jets.

Boeing said that it needed the second assembly line in order to "expand our production capability to meet the market demand for the airplane" and that it chose the Charleston site due to the component work already being done on the property.

However, the announcement came during a period of turbulent relations with its Washington-based union, leading to allegations that the plane-maker was attempting to illegally circumvent the union. Boeing has since allegedly fought any effort by Charleston workers to unionize.

Boeing said in 2020 that it would consolidate 787 production in Charleston instead of splitting it between South Carolina and Washington, a move which was completed the following year.

TPG had a chance to tour the factory last December ahead of an event marking United Airlines' new order for up to 200 airplanes .

Saying that Boeing makes the Dreamliners at its factory is a bit misleading because Boeing — just like Airbus, Embraer and other airframe makers — doesn't actually manufacture much of the plane itself.

More: The 787 Dreamliner: What are the differences between an -8, -9 and -10?

Instead, the company outsources components to specialized manufacturers, while building a few parts itself. Then, Boeing gathers each of the components and assembles them as the final product.

So really, the Charleston facility is more of an assembly plant.

Because of this, as you drive around the facility, which is located on the grounds of the airport, you won't only see 787s in various states of completion. You'll also spot a rare aircraft type: Boeing's custom "Dreamlifter."

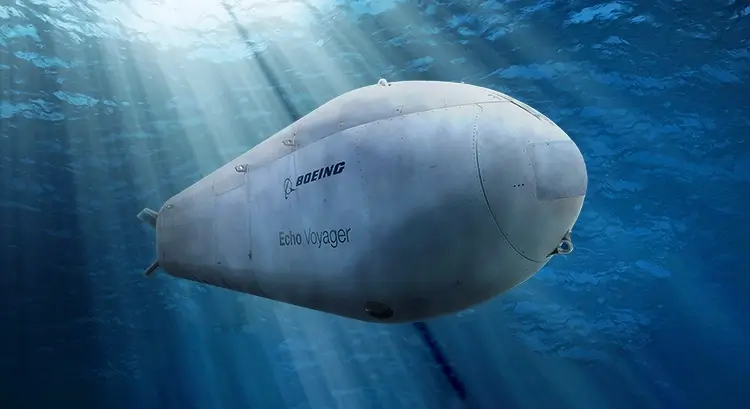

The Dreamlifter is a converted 747-400 with roughly triple the cargo volume thanks to its bulbous hull. Boeing designed the type in the mid-2000s specifically to transport large components for the 787 — such as wings — from suppliers to its manufacturing plant. Other oversized cargo aircraft at the time were too small.

The four Dreamlifters, which are operated for Boeing by cargo carrier Atlas Air, primarily pick up Dreamliner wings, made by Mitsubishi Heavy Industries in Japan, as well as several fuselage sections, frames, horizontal stabilizers and other parts from Leonardo in Italy, and drop them off in Charleston.

The Dreamlifters also deliver disassembled sections of the main fuselage, which are built by several suppliers including Spirit AeroSystems in Wichita, Kansas, Leonardo in Italy and Kawasaki in Japan. Meanwhile, thousands of other components are shipped using a variety of modes of transportation.

During TPG's visit, two of the Dreamlifters were on-site.

Boeing still builds some components itself, though — in particular the aft section, or back, of the airplane.

Unfortunately, Boeing asked us to agree not to photograph some parts of the facility, since it uses proprietary technology and methods in the manufacturing process. Still, we were able to get a look and take photos in some areas.

Once the aft section is completed, workers bring it over to a final assembly building.

There, the aft section is joined to the fuselage, and the wings and other structures are attached to the main body. The plane moves down the assembly line, and the aircraft interiors are installed, along with flight control systems. The vertical stabilizer has already been painted by the time the plane enters final assembly, and the livery is applied to the rest of the aircraft once it completes its run through the assembly line.

Finishing touches are put on, and each individual airplane is flown for a grueling test program before being delivered. During TPG's tour, a 787-9 bound for Turkish Airlines landed after returning from nearly three hours of testing over the Atlantic Ocean.

The Charleston facility has 787s parked all around waiting to be delivered. The Federal Aviation Administration ordered 787 deliveries to pause in mid-2021 after numerous concerns arose surrounding Boeing's quality control process in Charleston. Deliveries resumed late last summer .

Because of the year-plus pause in deliveries, which came just as air travel demand was beginning to return following pandemic-era lows, Boeing is working to get a backlog of completed airplanes to airline customers.

Between the pandemic and the delivery pause, the company also slowed the production line. Boeing is targeting a rate of five completed Dreamliners each month, according to Lisa Fahl, senior director of quality.

The line peaked at 14 new airplanes per month between Charleston and Everett, Fahl said, suggesting that output could scale up in the future.

It's not clear when production will speed up, but as United's order demonstrates, there's heavy demand for new Dreamliners — and there will likely continue to be for years to come.

Boeing Tours

Boeing future of flight and boeing everett factory tour.

Boeing Future of Flight is one of Washington State's premier aerospace attractions, welcoming guests to enjoy the Boeing Everett Factory Tour, Gallery, Sky Deck and Boeing Store. Boeing Future of Flight is located in Mukilteo, WA next to Paine Field and the Boeing Everett Factory, just 25 miles north of downtown Seattle.

Step inside the world's largest factory for a behind-the-scenes look at the Boeing Everett Factory and 777 assembly line. Each tour is an 80-minute guided experience with a front row view of current airplane production, the Everett site’s history, and the central role it plays in the future of commercial aviation. Tours are available Thursday–Monday.

Learn more about the Everett, WA tour

James S. McDonnell Prologue Room Air and Space History Exhibit in St. Louis

The James S. McDonnell Prologue Room Air and Space History Exhibit showcases the pioneers of aviation, their achievements and those of the thousands of workers who turned dreams into reality. The Prologue Room is located in the Boeing-St. Louis headquarters adjacent to Lambert-St. Louis International airport. The Prologue Room is open for self-guided tours weekdays during June, July and August only. Guided tours are available to groups of 10 or more throughout the year.

Learn more about the St. Louis tour

Travel news, reviews and intel for high-flyers

Sign up for our weekly newsletter

Go behind the scenes at boeing: factory tours are back.

Boeing's Everett factory, renowned as the largest building in the world by volume, once again opened its doors to the public on October 5

by Enrique Perrella

November 1, 2023

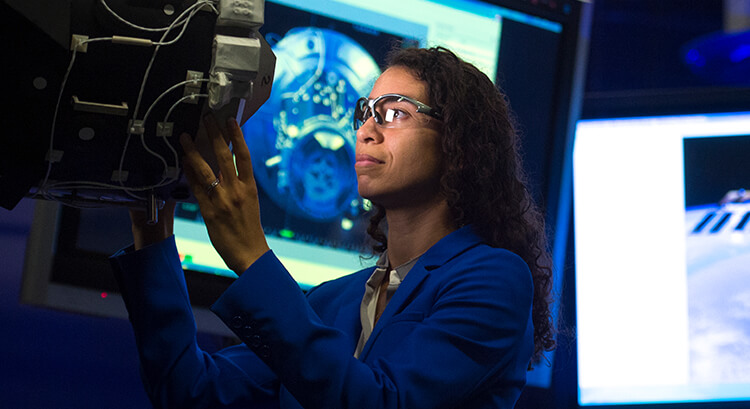

Photo: Courtesy of Boeing Commercial Airplanes

After a lengthy hiatus due to the COVID-19 pandemic, the Boeing Factory Tours are back, offering aviation enthusiasts and curious minds a chance to witness the magic of aircraft production.

For years, the Boeing Factory Tour has been a sought-after experience, attracting more than six million visitors from around the globe since its inception in 1968. The tour provides a glimpse into the fascinating world of aviation, with a behind-the-scenes look at the assembly line of iconic Boeing aircraft, which included the 747, 767, 777, and 787 Dreamliner.

Christi Medlyn, Boeing Future of Flight general manager, shared the excitement surrounding the reopening with Business Traveler USA .

“We’ve been closed for the tour portion of the experience for three and a half years. In the meantime, we invested in this space to give people a great brand experience for Boeing. It’s not just about airplane manufacturing; it’s about the full enterprise,” she explained.

A Renewed Factory Tour

Boeing’s Future of Flight location has undergone a transformation over the past few years to complement the factory tour. It now offers an immersive experience that covers various aspects of Boeing’s operations, including sustainable fuels, autonomous flight, and satellite technology.

In addition, hands-on activities and STEM learning opportunities have been introduced, allowing visitors to engage with drones and robots.

Visitors will notice several enhancements to the Boeing Factory Tour experience. The new route through the factory offers a unique perspective, taking guests from the Boeing Future of Flight Museum to the massive Everett factory, where tens of thousands of employees support airplane production.

The tour also includes access to the site’s underground system of factory tunnels and an observation balcony providing an exclusive, sweeping view of the current 777 assembly line where Boeing’s future flagship, the 777X, will also be manufactured. Lufthansa and Emirates are the first two airlines expecting to take delivery of the new variant of the Triple Seven.

Photo: Boeing 777X. Courtesy of Boeing Commercial Airplanes

Furthermore, visitors are treated to a comfortable bus tour that takes them through various sections of the airport tarmac. The journey starts from the area where new planes are fueled for the first time and continues to where Boeing 737 fuselages arrive on train wagons from Wichita, Kansas.

Sometimes, brand-new Boeing 777s without engines can be spotted, and other rare planes like Boeing 767 military tankers can be seen as they are prepared for delivery. During every portion of the tour, a knowledgeable guide provides detailed explanations of every aspect and responds to any questions from curious visitors.

However, the tour isn’t the only attraction. Boeing Future of Flight features the Boeing Gallery, showcasing nearly 150 past, current, and future Boeing products and services, including the intriguing Passenger Air Vehicle (PAV) or personal flying car.

The Above and Beyond exhibit offers immersive simulations, and visitors can snap selfies with the Destiny Module from the International Space Station.

The open-air Sky Deck provides breathtaking views of Paine Field, the factory, and the enchanting North Cascade Mountains in the distance. It’s not unusual to spot brand-new planes parked on the deck, preparing for their journey into the skies.

And for those looking to take home a piece of aviation memorabilia, the Boeing store offers a wide range of souvenirs, from sweatshirts to scale model jets, coffee mugs, and vintage Boeing pilot jackets for kids and adults.

Overwhelming Response

The reopening of the Boeing Factory Tours has been met with overwhelming demand. Visitors have expressed their excitement and appreciation for the improved experience.

“It has been overwhelmingly positive, as we have been sold out every day. The pent-up demand and excitement around our product has been contagious. We are pleased with the positive visitor reviews received so far,” Christi Medlyn said.

“We’ve invested in every aspect of the experience, from the script to the exhibit content. We’ve added new elements and updated the storytelling.”

“Even though the experience is a bit different from the last time, we have made significant investments in every aspect. You will see the difference even while walking down the booth hallways,” Medlyn added.

Focus on the Boeing 777

While the tour has shifted its focus from the 747 to the 777 experience, it continues to captivate visitors, old and new, with its rich history and innovations in the world of aviation.

With the entire assembly line for the 787 Dreamliner now operational at Boeing’s South Carolina plant, the facility at Paine Field is exclusively dedicated to the Triple Seven family of planes. This includes the present 777 Freighter, along with the new 777X, along with the occasional 767 Freighter.

“After the 747 and the 787 were no longer being manufactured in Paine Field, we had to alter our route,” Medlyn explained. “As a result, we are now focusing on improving the 777 experience while incorporating new elements that highlight the entire family of Boeing Commercial Airplanes. We aim to discuss sustainability and introduce fresh perspectives to our storytelling.”

“So, we looked at everything from the script to the exhibit content. We added a little bit of Boeing history that you’ll see in the theater experience through a video at the beginning of the tour.”

Whether you’re a seasoned aviation enthusiast or just curious about the marvels of flight, the Boeing Factory Tours are ready to deliver an unforgettable experience you’ll be eager to share with your friends for months to come.

So, mark your calendars, aviation fans, because this is a rare opportunity to step inside the world of Boeing, where dreams of flight become reality. The Everett factory, Boeing’s crown jewel, is ready to inspire and educate once again.

Most Popular

Related stories.

Air Canada Announces New Routes to Europe: Here’s What’s Coming in 2025

Star Alliance Strikes Back at SAS Move to SkyTeam with Bold Status Match Offer

European Union to Force Airlines to Report Vapor Trails

Privacy Overview

- Advertising

Inside the Boeing South Carolina B787 Factory

In November 2009, Boeing broke ground in North Charleston, South Carolina, on a revolutionary manufacturing facility for the B787 Dreamliner.

Final Assembly

The 787 final assembly building opened in 2011, provide expanded production and delivery capability to help the company fulfill orders for 787-8 and 787-9 from more than 60 customers. worldwide. The first 787 Dreamliner built in South Carolina rolled out in April 2012. By the end of the decade, Boeing plans to increase total production to 14 Dreamliners per month.

In final assembly, the three main fuselage sections, wings, horizontal stabilizer, vertical fin, and tailcone of the 787 are integrated. Teammates then install the engines, landing gear and other systems.

B787 Operation Cycle

Boeing South Carolina is the only site that has the full production cycle –“freezer to flight”.

Freezer is the fabrication from raw composite material. (which is kept in a freezer)

From Fabrication, some assemblies go to Puget Sound and the others go to Final Assembly just next door.

Next is decorative paint.

After paint, airplanes go to the Flight Line for fuel, testing.

Final step is delivery.

The new 787-10 Dreamliner will be built exclusively in South Carolina. At 224 feet (68.27 meters) in length, the 787-10 will be the longest Dreamliner to date. Carrying 330 passengers in a two class configuration.

Aftbody and Midbody

Every 787 aftbody and midbody is build in South Carolina, then some of them shipped to Everett, Washington by Dreamlifter and some of them were moved across by enormous cranes to the final assembly position at South Carolina.

The carbon-fiber tape used in the 787 is approx. 6.4mm wide and 0.2mm thick.

If all the carbon fiber used in a single 787 Dreamliner were streteched out in a line, it would reach from Charleston, SC to Los Angeles, CA - a distance of 2,200 miles.

The 787 is the first airliner with a fueslage composed of one-piece composite barrel sections rather than the thousands of aluminum sheets used in conventional airplane fuselages. This construction creates a lighter structure that uses 1.2 million fewer fasteners than the structure of a non-composite airplane.

Interiors Responsibility Center

The interiors responsibility center team fabricates and assembles 787 Dreamliner interior components, including stowage bins, closets, partitions, ceiling panels, class dividers, overhead crew rests, video-control stations and flight attendant modules.

Singapore Airlines became the world's first Boeing 787-10 customer.

Very nice and interesting article and visuals. How did you go about to get permission from Boing to take pictures in their assembly hall, etc. Thank you.

Does the Charleston factory offer any public tours of their facility outside of these dedicated media events?

I did ask this but seems no public tour in Charleston yet! 🙁

where’s the indoor sunglasses-wearing selfie?

You’re way way too good to be on Boarding Area 🙂

Awesome article!

Love the details..

– Happy Boeing investor

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Notify me of follow-up comments by email.

Notify me of new posts by email.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

AEROTECH® Americas

Boeing Charleston facility/plant tour

Date: March 25, 2019 Time: 1:00 – 3:45 p.m. Price: $50 (make selection during event registration)

Tour Timeline

The maximum tour limit for is 50 persons; reserve your seat by March 8, 2019.

Tour guidelines:

- Visitor badge must be worn at all times.

- No cameras, video recorders, or camera phones are permitted inside the plant as defined in Boeing Policy, PRO-2783.

- Remain with escort at all times

- No open-toed shoes or open heels

- No high-heeled shoes: Heels must be shorter than 2-in high with a heel base larger than 1-in square.

- Visitors must adhere to the tour path as defined by their tour guide.

- Boeing escorts will remain with their visitors at all times and visit only those areas defined on the visitor badge

- Boeing is a tobacco-free workplace, and tobacco use of any kind is prohibited on Boeing property.

Sign Up for Updates

Virtual Site Tours

See innovation in action with a series of Virtual Site Tours hosted by Boeing. Students will be transported around the U.S . to visit unique Boeing facilities, where they’ll learn more about the people and products leading the way to the future of air travel. Each video is paired with a companion activity that incorporates project-based learning, student collaboration, and hands-on STEM problem-solving

Boeing Unmanned Refueling Facility: St. Louis, MO

Get an inside look at the future of aviation at a Boeing facility that manufactures the world’s first unmanned refueling aircraft. See how drone technology is being used to revolutionize aircraft capabilities for the US Navy, and meet the pilots who control this amazing technology remotely from a desk! Students will meet a variety of dedicated Boeing team members as they tour a ground control station and go aboard a state-of-the-art aircraft carrier.

Boeing Training and Professional Services Campus: Miami, FL

Visit a Flight Training Center where the people who work on airplanes are trained in keeping passengers safe. Get a behind-the-scenes look at the state-of-the-art facilities and rigorous training processes that are used to prepare everyone from mechanics to pilots to flight attendants for their role in passenger safety. Students will be introduced to a variety of Boeing team members as they tour the structures lab and go inside a cutting-edge flight simulator.

Boeing’s Vertical Lift Division: Philadelphia, PA

Go behind the scenes of one of the most advanced helicopter manufacturing centers in the world to learn how vertical lift vehicles are created. Visit Boeing’s complex in Ridley Park, Pennsylvania, where over 6,000 employees work daily to build and restore the powerful H-47 Chinook and other aircraft. Students will meet a chief test pilot and discover how extended reality technology is used to solve problems on the manufacturing floor.

Boeing Additive Manufacturing Center: Auburn, WA

Explore the amazing ways Boeing uses additive manufacturing—better known as 3D printing—to design and manufacture thousands of its parts and tools. Take a tour of the Center of Additive Manufacturing Excellence, where parts, tools, and prototypes are created to support state-of-the-art aircraft. Students will hear from a variety of experienced manufacturing professionals and learn how specialized simulation software and lasers are used to help streamline the process.

Spectrolab Solar Panel Factory: Los Angeles, CA

Discover the special piece of technology powering everything from the International Space Station to satellites that enable mobile phones, internet and weather forecasting here on Earth. Visit Boeing’s state-of-the-art Spectrolab where high-efficiency solar cells are created to support life on Earth and human exploration of space. Explore the history of satellites and find out how Spectrolab employees simulate the sun!

787 Dreamliner Factory: North Charleston, SC

Get an inside look at the Boeing facility where the energy-efficient Dream l iner airplanes are built. Watch as many diverse teams come together to create a finished product that lives up to Boeing’s principles of safety, quality, and integrity. Students will explore a sustainably powered, z ero waste - to- l andfill facility to see sustainable innovation up-close, then bring aircraft design to life with a fun paper airplane activity.

Sign up for Updates

Boeing Delivers First North Charleston-built 787-9 Dreamliner

Boeing has delivered the first 787-9 Dreamliner assembled at its North Charleston, S.C., facility to United Airlines. The airplane also marks a milestone for the 787 program as the 250th Dreamliner to be delivered.

“In 2012, we delivered our first South Carolina-built 787-8, and less than three years later, we’re celebrating another significant milestone – our first 787-9 delivery,” said Beverly Wyse, vice president and general manager, Boeing South Carolina. “This is an incredible achievement for Boeing, and I’m proud to be a member of the Boeing South Carolina team.”

In the first quarter of 2013, Boeing South Carolina teammates began fabrication, assembly and integration of the aft and mid fuselage sections for the first Boeing 787-9 and delivered them to Everett Final Assembly. In November 2014, work began on the first South Carolina-built 787-9 when the first aft and mid sections were delivered to Boeing South Carolina Final Assembly. The airplane rolled out to the flight line in January 2015 and completed its first flight last month.

“Our customers have told us they love flying on the Dreamliner, and we’re excited to mark yet another first for the aircraft with this delivery from Boeing South Carolina,” said United’s Vice President of Fleet Ron Baur. “We were the first North American carrier to fly the 787-8 in September 2012 and the first to fly 787-9s in September 2014. The Dreamliners have allowed us to fly longer distances with greater fuel efficiency and open new direct routes such as Los Angeles to Melbourne, while providing our customers and employees with a more comfortable flying experience.”

This is the fourth 787-9 for United Airlines, in addition to the 12 787-8s the airline already has in service.

The 787-9 complements and extends the 787 family. With the fuselage stretched by 20 feet (6 meters) over the 787-8, the 787-9 is designed to fly up more passengers and cargo farther with the same exceptional fuel and environmental performance: 20 percent less fuel use and emissions than the airplanes they replace.

- Boeing & Aerospace

Boeing plans for N. Charleston reveal doubling of facilities

Share story.

WASHINGTON — Boeing will more than double the number of parking slots for finished jetliners and add a second final-assembly line at its plant in North Charleston, S.C., according to a recent document that also suggests the newest version of the 787 Dreamliner may not be built in Everett.

The public filing details how Boeing will grow at its 265-acre campus next to Charleston International Airport, as well as on 468 acres of adjacent land the state bought this month to lease long term to the company.

Boeing outlined its plans in papers filed with the U.S. Army Corps of Engineers seeking approval to use federal wetlands. The disclosure was required because Boeing proposes to excavate or fill almost 154 acres of federal waters to level the ground for construction.

Included are nearly 20 acres of wetlands or upland buffers that were protected under a restrictive covenant when the Boeing plant was built in 2011.

Most Read Business Stories

- What's behind Nordstrom family's $3.8B play to take control of company

- Nordstrom Family Bids to Take Chain Private for $3.8 Billion

- They made a movie about Trump. Then no one would release it

- Guggenheim rises in the desert as Abu Dhabi morphs into expat hub

- Crypto owners more likely to have psychopathic traits, study says

Most immediately, Boeing will expand its flight line — where finished jets are parked for engine and fuel testing before test flight — from seven stalls to 16. The plan also includes a previously announced paint facility so that finished Dreamliners can be delivered to customers in North Charleston without first being flown to Fort Worth, Texas, for final painting.

Starting in 2016 or after, the document says, Boeing will enlarge its existing final-assembly plant southward to fit in a second, parallel production line.

Analysts have speculated Boeing was making room for final assembly of the 787-10, the newest and longest derivative of the popular Dreamliner — or for perhaps even the 777X that’s the focus of a pending multistate competition.

The latest details of Boeing’s expansion plans reinforce indications that the 787-10 likely will get built in North Charleston, said Scott Hamilton, an aviation analyst with Leeham in Issaquah.

Boeing is expected to announce the final-assembly site for the 787-10 in March.

Currently, Boeing’s widebody plant in Everett assembles both the base 787-8 model and the stretch 787-9. North Charleston handles final assembly for the 787-8 and is to begin producing the 787-9 next fall.

At 224 feet, the 787-10 is 40 feet longer than the 787-8. The current North Charleston plant is nearly 1,100 feet long, according to scale maps in the public notice released by the Army Corps of Engineers and the South Carolina Department of Health and Environmental Control.

That’s room enough to fit four 787-10s in line. In Everett, Hamilton said, a nose-to-tail 787-10 assembly line would have to be at an angle, which is less efficient.

Boeing is proposing to replace North Charleston’s single U-shaped assembly line with two parallel lines by stretching the plant by about 800 feet.

Boeing’s long-term plan for North Charleston calls for adding 3.4 million square feet of manufacturing space to the west and south of the current plant, near the intersection of Michaux Parkway and International Boulevard. Also included are additional office space and parking.

Boeing recently gave up first right of refusal to buy an additional 488 acres of land west of the airport, saying it could always come back to it.

Jack Jones, general manager of Boeing’s South Carolina operations, had steadfastly declined to specify the company’s plans for all the available land.

Boeing is producing a total 10 Dreamliners a month from the two assembly lines in Everett and the single line in North Charleston but doesn’t break out each plant’s output. The combined rate is to quicken to 12 a month by 2016 and to 14 a month by 2019.

That scenario calls for seven Dreamliners a month to roll out of North Charleston by 2018-19. On top of that, Boeing is building a North Charleston plant to design and assemble engine inlets for the 737 MAX to be produced in Renton.

That might keep North Charleston too busy, Hamilton believes, to have a shot at landing the 777X if Puget Sound-area Machinists again reject Boeing’s contract offer Friday.

The 777X “is more than I think Charleston can handle,” Hamilton said. “But Boeing being Boeing, you never know.”

Connie Kelliher, spokeswoman for International Association of Machinists District 751, which represents Boeing’s Puget Sound-area assembly workers, said the union believes tooling Boeing installed in the Everett plant is equipped to handle the 787-10’s longer fuselage.

What’s more, Kelliher contends, analysts and Boeing workers think the only way the company can meet its accelerated production for the Dreamliner would be to keep the second “surge” line in Everett going permanently.

Kelliher said Everett is slated to ramp up to nine 787s a month in early 2014, far outpacing North Charleston.

“We are certainly producing more than our share of 787’s right now,” she said.

The public in South Carolina has until Jan. 20 to comment on Boeing’s expansion plan. In exchange for use of federal wetland near the Ashley River, Boeing has offered to preserve 3,618 acres of nearby Cooper River watershed as well as clean out 150 acres in another watershed to restore natural plants and animals.

Kyung Song: 202-383-6108 or [email protected]. Twitter: @KyungMSong

Grow your career in South Carolina

Search by Location

Search by Keyword

Filter Results

- Business 12

- Business Support Services 11

- Data Science & Analytics 1

- Engineering 9

- Engineering - Electronic and Electrical 3

- Engineering - Production 1

- Information Technology 1

- Internship 10

- Manufacturing 1

- Seattle Area Manufacturing 17

- Supply Chain Management 2

- Washington State 6

- United Kingdom 2

- United States 1

- Karnataka 5

- South Carolina 1

- Subcarpathia 4

- Bengaluru 5

- Charleston 1

- Hazelwood 1

- Lossiemouth 1

- Mascoutah 5

- North Charleston 1

- Oklahoma City 2

- Rzeszów 4

- San Antonio 2

- 00000435025 1

- Relocation Assistance 1

- Non-Manager 1

We're committed to environmental stewardship — an important pillar of our broader sustainability strategy to help make the world better for future generations.

Join our team of innovators and dreamers, engineers and designers, cybersecurity experts and technologists. This is where you'll help build tomorrow today.

See how everyone here is an involved and engaged member of our communities.

See how we innovate and operate to make the world better.

Apply for opportunities in engineering, product support, IT, manufacturing and other areas.

Oklahoma City is where you’ll shape tomorrow’s innovations.

Mother and daughter duo Denise and Kay push aerospace innovation forward every day.

Fascinated by kit airplanes as a child, Tresha is now chief engineer for the world’s most efficient twin-engine jet.

With a curiosity inspired by school projects, Kariza now helps develop sustainable aerospace technology.

Learn how Boeing employees can earn a bonus by referring external hires.

The Boeing Pre-Employment Training Program (BPET) allows students from pre-certified academic manufacturing programs to skip the interview process when applying for specific manufacturing jobs at Boeing.

Our 12-week paid fellowship connects individuals with training, networking opportunities and hands-on experience.

Our three-year apprenticeships offer diverse experiences and prepare you to work on our aircraft.

Boeing’s Return Flight Program provides people with a pathway to return to their careers after an extended break.

Christina Upah believes problem-solving starts with a great team.

Ida Eggeblad uses interpersonal skills to connect teams across countries

How a conversation at a career fair led business operations leader, Jennifer, on an unexpected career path.

From intern to leader, east to west and in between, Laura shares how business and technology merge

Rodney Kruse shifts his perspective each day by asking, “What have I learned?”

A teammate’s skill for seeing the bigger picture helps her lead transformation at work and in her personal life.

'At Boeing, I've found a supportive environment where my attention to detail and focus are valued.'

'My team and I are using advanced tools and technologies to help chart Boeing’s future.'

Suellen achieved her dream to become a Boeing engineer. Now she’s mentoring our future leaders.

Elizabeth and Maggie share their stories on celebrating the perspectives and accomplishments from LGBTQIA+ employees and allies across Boeing.

Meet Melanie Brisbane, recent graduate and human resources professional. See how Melanie reached her dreams with help from our tuition assistance program.

Earn as you learn technical skills and receive credentials that can set you up for success.

Read how Dr. Catherine Sinclair, a software engineer with Boeing Defence Australia, increases awareness of domestic abuse and supports gender equity.

Romina Cutescu, a systems engineer, works on programs that are critical to homeland security.

Meet Anika Bell, an Army veteran and university recruiter who’s passionate about building diverse connections for an innovative future.

Aurelina Prada started at Boeing as an aircraft mechanic. Today, she's advocating for gender equity as a supply chain senior manager.

Since interning, Emily completed rotations in four business units and worked on the cargo air vehicle program. Today, she is a flight test conductor for the T-7A program.

Boeing's partnership with Thurgood Marshall College Fund is an initiative supporting HBCUs through campus recruitment, career immersion, scholarships, and more.

Find out how Enrica is advancing her career at prestigious universities around the world with tuition assistance from Boeing.

Anthony 'Tony' Crutchfield, Boeing vice president and retired lieutenant general, shares decades of leadership experience with students and early career professionals from underrepresented communities.

Angelie has been with Boeing for 12 years and was diagnosed with autism in April 2019. Through her story, she inspires others to overcome adversity.

Nathan helps our defence customers make decisions using the power of modelling and simulation.

Meet Kay and Denise, inventors of an adhesive removal tool and an inspiration to other innovators across our company.

If you need a reasonable accommodation for any part of the employment process, please contact us.

Shanying Zeng is Boeing’s technical expert on the International Aerospace Environmental Group, which is helping Boeing find environmentally progressive alternatives for hazardous chemicals and material used in commercial and military aircraft.

Read how our Leading in Manufacturing training helped Jacob become a people-focused leader.

Meet Lee, a manufacturing engineer in Boeing’s Melbourne factory who has worked on commercial and defense aircraft, including the first Australian-made autonomous military aircraft, known as the MQ28A Ghost Bat.

Our tuition assistance program pays your institution directly so you don’t have to pay out of pocket. Learn about our generous funding for courses, certificates, undergraduate and graduate degrees.

Meet Danielle and Ankita, two teammates who are breaking biases with the help of allies.

Product security engineer Anna Guthrie builds resilient technologies to protect against cyberattacks. In this interview, she offers a glimpse into a day in her life with our growing cybersecurity team.

Three teammates champion a new approach to helping overcome the “mid-career crisis” and increasing diversity at all levels.

Engineering manager Aslihan Karlidag uses Boeing’s digital learning opportunities to keep her fears at bay

Senior software manager Chad Peterson knows that growth happens outside the comfort zone

Vice president Tresha Lacaux landed her dream internship at Boeing. Today, she’s landed her dream role

Discover how our Neurodiversity at Work program helped Thomas launch his software engineering career.

Meet Dr. Rongsheng “Ken” Li, a Principal Technical Fellow who has been awarded for his work in aerospace guidance, navigation and control systems.

Discover how Suba Iyer turned her fascination with how things work into an engineering career.

Meet two systems engineers who are contributing to the next era of spaceflight.

Read how Sanh Ha, an engineer who is deaf, applied innovative thinking to safely overcome obstacles during a test flight.

Meet Nic, a leader in the UK who is advancing equity and entrepreneurial innovation to solve aerospace challenges.

A lifelong interest in chemistry sparked this engineer to desegregate lunch counters in 1960 and unveil cutting-edge technology in Boeing laboratories 50 years later.

Teresa is a product engineer and inventor with multiple patents. Learn how she's helping to close gaps for Asian women in STEM.

Bo designs and develops software and hardware that supports the Wedgetail's missions. Watch the video to learn how his work has an immediate impact.

Be aware of fraudulent job offers purporting to be from The Boeing Company and/or its affiliates. Learn what to look for.

Read how Chantel, a manager in workforce and engineering, is breaking ground in representation and aerospace history.

Marvi applies her love of invention to challenging problems, and works towards her personal mission: to serve as many people as possible.

Read about Nelson's journey from the soccer field to becoming an accomplished engineer and leader at Boeing South Carolina.

Meet Susana, a supplier quality specialist in Mexico who's using problem-solving skills to drive operational excellence.

Learn how our partnership with SkillBridge is supporting veteran teammates in discovering their next mission.

An inclusive approach is helping Jacqueline drive sustainable aviation in Southeast Asia.

From challenges to bright spots, Boeing’s KC-46 chief mechanic shares tips and lessons learned to help future leaders.

Meet Jesus Sanchez, a power machine operator in Auburn, Wash. See how Jesus used our tuition assistance program to obtain an associate degree in business.

Boeing's partnership with Thurgood Marshall College Fund helped these two students land their dream jobs.

As a global equity, diversity and inclusion leader, Zan works to ensure everyone feels they belong.

Alex Campos, a Boeing Missile Defense contracts administrator and U.S. Navy reservist, shares his advice for staying on mission.

Read how Kristin Innes and her partner Bonnie are growing their family with help from Boeing's fertility benefits.

Nick Perry shares why understanding, identifying with and talking about disabilities helps reduce stigmas.

Meet Kim, Greta and Miwa: Three women who took chances and developed their careers on their own terms.

Meet Jimmy, an Air Force veteran and aviation safety coordinator that helps teams operating the F/A-18F Super Hornet and EA-18G Growler get home safely.

Darcy and Susan discuss their experiences as transgender women and the effects inclusion — and exclusion — have on their time at work.

Engineers Debra and Stacia discuss the importance of community connection and making an impact through even small actions.

From the Rosebud Reservation in South Dakota to leading attack helicopter programs in Mesa, AZ., Kathleen “KJ” Jolivette inspires STEM interest among Native American students.

Meet Ty'Quish, a mechanical engineer who has helped design and build the next-generation assault helicopter.

Our software engineering challenges are immense. But the possibilities are even greater. Learn how our team is harnessing the power of future-forward computing.

A a modeling and simulation engineer for Boeing Ground-based Midcourse Defense, or GMD, Kyle mostly deals in a world that’s conceptual, using a modeling system to simulate and predict how a customer request will perform in a real-world scenario.

Discover how Rakesh and the design engineering team at the 787 Interiors Responsibility Center in India innovate and grow.

Faced with caring for two sick family members, Sandra Lankford leaned on Boeing's caregiver benefits for support. Watch Sandra's story.

Read how Sarah Wauahdooah, a manufacturing research and development engineer, applies her robotics expertise on the V-22 Osprey program.

Satyaki helps to keep the Australian Army’s CH-47 Chinook helicopters flying around the clock.

Shruthi discusses innovating with her design build team, and taking her next career step as a manufacturing engineer at Boeing in India.

Stephanie Yount, engineer and recent Leadership Next graduate, discovers she’s most comfortable when she’s completely uncomfortable.

Meet Boeing finance leader Terrence Chance, and discover the breadth of the experience that's shaped his career.

We are an equal opportunity employer.

Dalena Nguyen, a Talent Acquisition Advisor, shares her top tips for making a great first impression when interviewing by phone or online.

Discover how our digital learning resources helped Boeing India teammate Antara upskill.

Abbey Carlson, a former Boeing intern, shares her two major milestones: graduating from college and accepting her first job with Boeing.

A Senior Composite Engineer at Boeing’s Satellite Development Center, Francis, says each patent represents a step toward achieving her childhood goal to make space safer.

Glen shares a personal story about a family member who was involved in an auto accident. For years after Glen avoided flying due to safety regulations that prohibit passengers from sitting in their own wheelchairs on airplanes.

Meet Hana McKee, an engineer whose curiosity inspires her to innovate the next generation of rotorcraft.

Meet Jae, a systems engineer on the world’s leading airborne early warning and control aircraft, Boeing’s E-7A Wedgetail.

What Marcie Purser, program management specialist, brings to the table is highly valued at Boeing: lasting connection.

Electrical engineer Marcela Angulo works on next-generation defense technology and inspires Hispanic students to get involved in STEM.

Learn how one of our development programs – a partnership with MIT – is helping an engineer get on a path to executive leadership.

From space to defense, senior software and project engineer, Kimberly Sledge, inspires the next generation of Black women in STEM.

Chandler is pursuing her passions thanks in part to our development programs and tuition assistance.

From making repairs on aircraft to building spacecraft, Oborsouis "OB" has had his hands in a little bit of everything.

Suzanne Brown is an avid sailor and chief engineer for the Patriot Advanced Capability-3 Missile seeker program.

See how Jennifer helps engineers understand assembly principles that lead them to design better airplanes.

Kristine Ramos, design engineer, goes above and beyond to advocate for human spaceflight.

Meet Nixon, an engineer who uses our tuition assistance to stay on the cutting edge of emerging technology.

Meet Indica Bennett, an engineer whose hobby inspired a dream job.

Meet Dama, an engineer and manager who strengthens our company by being a cultural and technical integrator.

Read how Kaomi Hashimoto has grown her career across continents, while supporting our next generation of leaders.

Meet Wilton, a Quality manager for the Space Launch System program who helps create a culture where everyone can speak up.

From aircraft assembler to avionics engineer, Vadym Vasylyshyn grew his career with our tuition assistance program.

Learn how 737 MAX mechanics squeeze through a tight opening to perform final inspection and cleaning before testing.

Pete Kunz, Phantom Works chief engineer, describes opportunities that have shaped his career and shares tips for success.

As project manager for Ground-based Midcourse Defense, Rayni isn't bothered by roadblocks. Read her advice for career growth.

An operations manager and an analyst for the V-22 tiltrotor thrive on teamwork in the factory and at home.

Nadiya’s Cherokee Nation heritage guides a unifying approach with her team.

Meet Ronak, a Boeing India teammate who’s used our tuition assistance to grow his career, studying online and abroad.

Boeing's first Black Senior Technical Fellow grew from humble beginnings to executive leader and mentor.

‘It’s about technology and innovation that will transform aerospace as we know it.’

Discover a career with Phantom Works, Boeing’s advanced research and development division, and shape the future of aerospace. Apply today for engineering, cybersecurity, data intelligence jobs and more.

Join our Global Talent Network and sign up for Job Alerts to learn about additional opportunities.

Our Total Rewards program includes best-in-class benefits designed to meet your needs at every stage in life.

We're a company of inquisitive, talented people. Find out what's important to us and what inspires us to do amazing things together.

See what it means to be part of #TeamBoeing. Explore stories and learn how our people grow their careers while shaping the future of aerospace.

Our global presence includes employees and operations in more than 65 countries. Explore some of our locations.

See some of the most commonly asked questions about starting a career with Boeing.

Designed for college sophomores majoring in engineering, this program prepares our next generation of leaders to take charge.

We're committed to advancing equity, diversity and inclusion, and we make progress toward our 2025 aspirations.

Our hiring events are a great way to learn about our innovations and culture.

You can join the more than 18,000 veterans who chose Boeing to be their next mission.

Work on projects with a scope few companies can match in an entry-level role — where many of our senior leaders started their careers.

Gain hands-on experience and work alongside a team of industry leaders as you help build the future.

We’re proud of our 75-year partnership with South Korea. Join us and help revolutionize aerospace development from the heart of Seoul.

The most exciting advances in aerospace are being developed today in India. Join us and build a career at the center of our industry’s future.

Across 30 key locations in the UK, we employ more than 3,000 highly skilled teammates. And, after 80 years of success, we keep growing.

Whether you're a software engineer, systems engineer, or cyber analyst, help us solve tough challenges and contribute to the security of the nation.

Join us and contribute to next-generation aircraft, training, and defense products and capabilities.

We develop technologies that will shape the future of flight and we need your curiosity and unique perspective to help keep us innovating.

Learn how we continue to create opportunities for bright minds and see what makes this a great place to build a career.

As the largest aerospace company in the state, we play a vital role in the U.S. space and defense programs.

As we transform aerospace, your skills will take center stage. Join us and help connect, protect and explore our world and beyond.

For more than 90 years, we’ve partnered with Brazil and today you can join a team filled with creative minds who are building what’s next.

Explore what makes Boeing in Texas a great place to work.

For more than 50 years, we’ve worked closely with Japan to help create the future of aerospace and bring new expertise to our future-focused products.

Known for producing the Apache and Little Bird aircraft, we’re also home to centers of excellence in software, composites, wiring and fabrication.

Across our manufacturing plants, research and technology center, engineering center and propulsion sites, we’re developing new advances in flight.

At the center of aviation since 1916, many of our most innovative products are designed and built here.

Boeing is more than airplanes. More than satellites. More than cutting-edge cyber solutions. We work together with advanced technology on projects for the defense and intelligence communities. Join our Cybersecurity team.

Electrical engineers work closely with our customers to develop electronic and electrical systems for Boeing aircraft, and world-class autonomous robotic systems for space, terrestrial, and underwater hardware. Learn more about the team.

Our finance professionals play a key role in guiding critical business decisions and cutting-edge solutions for the world’s leading aerospace company. Learn more.

Flight engineers are essential to the development, safety and success of our products and solutions. Learn more about the team.

Learn how you can get access to cutting-edge technology and grow your skills through our Information Technology & Data Analytics Intern Program.

A chance to start your career designing and building our next generation of products.

Boeing HR professionals support our employees as they manage their career path, develop their teams and chart the course for career development. Learn how you can join the team.

Discover how you can make a difference at Boeing as an industrial engineer. Become part of a team that drives innovation across diverse technologies worldwide.

As a Test and Evaluation Engineer at Boeing, you'll ensure that our next-generation commercial and defense products and systems meet the highest standards. Join us as we continue to push the boundaries of aerospace.

As a software engineer at Boeing your code will power products that defy gravity and fly faster than the speed of sound.

With a career in supplier management at Boeing, you can help solve business challenges that are redefining an entire industry.

As a Systems Engineer at Boeing, you can help drive the overall design of innovative and high-quality products and solutions.

In our Business Intern Program, you can be part of a team that is helping shape the future of aerospace.

In our Supply Chain Intern Program, you can be part of a team that is helping shape the future of aerospace.

Data doesn’t work in silos — it needs to breathe and interact with other information in order to tell the whole story, not just parts of it. At Boeing, we’re working across our enterprise to let data and information drive our collective decision-making. Join our Data Science and Analytics team today.

As part of our Information Technology and Data Analytics team, you’ll support one of the largest corporate IT portfolios anywhere. Join us and help build the future.

Come build the future with Boeing and develop the next generation of aircraft, space and underwater vehicles and revolutionary approaches to manufacturing.

Mechanical and structural engineers at Boeing develop and apply innovative technologies that shape the future. Learn more.

Discover how you can make a difference at Boeing as a product security engineer. Become part of a team that drives innovation across diverse technologies worldwide.

At Boeing, our production engineers use their skills to build the future of advanced manufacturing. Learn more.

Every day around the globe, Boeing manufacturing employees build the future of aerospace. Join our team. Your future is waiting.

In our Finance Intern Program, you can be part of a team that is helping shape the future of aerospace.

Our teams in Ukraine provide engineering expertise, consultation services, research and technical assistance for our platforms and aircraft that fly worldwide.

Join a team of more than 4,300 people providing leading-edge aviation services for our defense and commercial customers.

Veteran, military spouse and engineer, Jenna believes there are many paths to success.

Joshua, a veteran of the U.S. Air Force, once helped repair our aircraft. Now he flies in them.

Tristan helps his team create experimental hardware designs for propulsion applications.

Adrian supports the efficiency and reliability of 777X wing structures through innovative design solutions.

Learn how Mya contributes to safety and certification standards for Boeing Defense, Space & Security.

Through Aerospace Xelerated, Eva supports aerospace startups, fostering innovation and industry advancement.

Elisa’s passion for aviation motivates her to enhance internal tools that improve collaboration.

Meet Niyathi, who manages projects for our Sustainable Aerospace Together Forum.

Sort by Relevancy Date Posted

1 Engineering - Production Jobs in Charleston

Filtered by.

- Charleston, South Carolina, United States

- Mid-Level or Senior Manufacturing Technology Analyst Charleston, South Carolina 09/04/2024 Save for Later

Jobs for You:

No recently viewed jobs.

No saved jobs.

Connect with us

Sign up for job alerts.

Be the first to know when new jobs are posted.

Join our Talent Community

Get updates about Boeing job opportunities, events and career information.

Veteran Talent Community

Transition to a career in engineering, product support, IT, manufacturing or other areas.

IMAGES

COMMENTS

Boeing said in 2020 that it would consolidate 787 production in Charleston instead of splitting it between South Carolina and Washington, a move which was completed the following year. TPG had a chance to tour the factory last December ahead of an event marking United Airlines' new order for up to 200 airplanes.

Our Story. Boeing South Carolina is the the home of the 787 Dreamliner, where the full cycle of 787 Dreamliner production happens - from freezer to flight. Our teammates fabricate, assemble and deliver the 787-8, 787-9, and 787-10 to customers all over the world. In addition to the Dreamliner assembly, Boeing South Carolina is home to Boeing ...

Get an inside look at the Boeing South Carolina facility where the energy-efficient 787 Dreamliner is built. Watch as many diverse teams come together to create an airplane that lives up to Boeing's principles of safety, quality, and integrity. After watching the virtual tour, download the DreamLearners activity, to learn what it's like to ...

Want to know how aerospace innovations get off the ground? Get an inside look at the Boeing South Carolina facility where the energy-efficient 787 Dreamliner...

Step inside the world's largest factory for a behind-the-scenes look at the Boeing Everett Factory and 777 assembly line. Each tour is an 80-minute guided experience with a front row view of current airplane production, the Everett site's history, and the central role it plays in the future of commercial aviation. Tours are available Thursday ...

The tour provides a glimpse into the fascinating world of aviation, with a behind-the-scenes look at the assembly line of iconic Boeing aircraft, which included the 747, 767, 777, and 787 Dreamliner. Christi Medlyn, Boeing Future of Flight general manager, shared the excitement surrounding the reopening with Business Traveler USA.

Boeing South Carolina is an airplane assembly facility built by Boeing in North Charleston, South Carolina, United States.Located on the grounds of the joint-use Charleston Air Force Base and Charleston International Airport, the site is the final assembly and delivery point for the Boeing 787 Dreamliner.Boeing opened the site in July 2011, after purchasing the facilities of suppliers Vought ...

In November 2009, Boeing broke ground in North Charleston, South Carolina, on a revolutionary manufacturing facility for the B787 Dreamliner. Recently, in conjunction with the World's First B787-10 delivery, Boeing have given a tour of its South Carolina facility.I was able to visit the final assembly, midbody, aftbody plant and interior responsibility center.

The DreamLearners program offers the opportunity for South Carolina students in 5th grade and students in specialized Science, Technology, Engineering, and Math (STEM) programs to tour Boeing South Carolina and learn about careers in STEM, advanced manufacturing, and aerospace. Boeing also offers the opportunity for classroom speaking events ...

Boeing South Carolina is the home of the 787 Dreamliner, where the full cycle of Dreamliner production happens - from freezer to flight. Our teammates fabricate, assemble and deliver the 787-8, 787-9, and 787-10 to customers all over the world. In addition to the Dreamliner assembly, Boeing South Carolina also is home to Boeing Research ...

Boeing's North Charleston factory is capable of producing all three variants of the Dreamliner - the 787-8, 787-9 and 787-10 - though Larson says "we're going to focus on -9s and -10s ...

0:54. NORTH CHARLESTON, S.C. - Boeing's Dreamliner assembly line here was set to take center stage for the company Sunday night at delivery celebration for the company's newest and biggest ...

Boeing Co. is consolidating 787 Dreamliner production at its final assembly plant in North Charleston. The highly-anticipated announcement about the move was made Oct. 1, 2020.

Posted By: SCMFG/Staff February 13, 2023. Boeing South Carolina (BSC) established a sizable presence in South Carolina in 2010 and has been "building the dream" in the state for the past twelve years. The company established final assembly operations of the Dreamliner 787 wide-body jet airliner in North Charleston and established a driving ...

A giant Boeing 787 model graces a visitor lobby at the company's Charleston, S.C., final assembly plant during a media tour on March, 25, 2018. Jeremy Dwyer-Lindgren, Special For USA TODAY

Under-construction 787s, on Monday, April 15, 2024, at Boeing South Carolina in North Charleston.

Boeing Charleston facility/plant tour. Date: March 25, 2019 Time: 1:00 - 3:45 p.m. Price: $50 (make selection during event registration) On an observation platform high above the sprawling Boeing Charleston manufacturing facility floor, you'll begin a tour of the assembly operations at the plant.

The Dreamlifter ferries parts from Italy, Japan, and Charleston, South Carolina to Everett for assembly. We were fortunate on our visit to see a Dreamlifter taxiing to the building where the 787 parts are unloaded. ... To reserve a Boeing Factory Tour, simply contact Boeing at 1-800-464-1476 or book online. These are the standard prices listed ...

787 Dreamliner Factory: North Charleston, SC Get an inside look at the Boeing facility where the energy-efficient Dream l iner airplanes are built. Watch as many diverse teams come together to create a finished product that lives up to Boeing's principles of safety, quality, and integrity.

Boeing has delivered the first 787-9 Dreamliner assembled at its North Charleston, S.C., facility to United Airlines. The airplane also marks a milestone for the 787 program as the 250th Dreamliner to be delivered. "In 2012, we delivered our first South Carolina-built 787-8, and less than three years later, we're celebrating another ...

At 224 feet, the 787-10 is 40 feet longer than the 787-8. The current North Charleston plant is nearly 1,100 feet long, according to scale maps in the public notice released by the Army Corps of ...

Historic delivery of 787 Dreamliner to Air India begins a new chapter of Boeing airplane production in Charleston region +1 843.767.9300 Target Industries. Doing Business Here. ... Production of the first South Carolina-built 787 began in mid-2011 and the completed airplane rolled out of the factory in April. Boeing South Carolina fabricates ...

Am I able to tour the Boeing Charleston facility? Commercial. I'm a current Boeing employee visiting Charleston soon for a short vacation. I was wondering if myself and a friend (he is not a Boeing employee) would be able visit/tour any parts of the site. We are both big aviation geeks so we'd love to see anything at all.

North Charleston, South Carolina Job ID 00000437352 Category Supply Chain Management Post Date Aug. 29, 2024. Apply Now Save Job Remove Job. Job Description. ... Meet Lee, a manufacturing engineer in Boeing's Melbourne factory who has worked on commercial and defense aircraft, including the first Australian-made autonomous military aircraft ...

One of the main reasons residents love living in Charleston is its thriving job market. The city's unemployment rate sits below the national average at 2.8%, providing jobs in major industries in Charleston include aerospace, automotive, defense, logistics, life sciences, and technology. With several hundred tech companies in the area and significant growth in IT jobs over the last five ...

Columbus upends 3-time state champion La Crosse Aquinas, avenging its playoff loss; 5 WiscNews-area high school football stars for Week 2; 5 high school girls golf stars of the week: Aug. 29 edition

Meet Lee, a manufacturing engineer in Boeing's Melbourne factory who has worked on commercial and defense aircraft, including the first Australian-made autonomous military aircraft, known as the MQ28A Ghost Bat.