Is Your Air Compressor Tripping the Breaker: Fix it today

There are two reasons an air compressor can trip a breaker, electrical and mechanical. Most commonly, the motor is pulling too much amperage but before diving into the electrical circuit. Inspect for mechanical issues, such as the pump being stiff or locked up. Inspect bleeder or loader valve. I run into this occasionally, I hate myself when I spend two hours testing circuits, and it should have been a fifteen-minute job replacing a bleed-off valve.

Safety first: safety glasses unplug the compressor. Visually inspect the compressor and surrounding area for obstructions to the mechanical parts of the compressor, such as pulleys, belts, pump, and the motor.

Before You Can Repair Your Breaker concern, let us save you some time by asking a few qualifying questions.

This is the first time plugging in this compressor, and the breaker tripped while running? a) my compressor is new b) my compressor is not new

my new air compressor trips breaker

The most common reason I find circuit breakers tripping with new compressors is too much load from combined amperage draw from multiple devices and tools on one circuit.

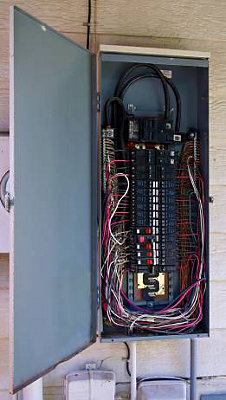

Sometimes on new compressors, the easiest way to cure this concern would be to move the compressor to a dedicated circuit large enough to handle the load. Moving the compressor may also identify a week breaker. If the breaker trips on one 15 amp breaker but not the other, The tripped one may be old and worn. I would recommend replacing that worn breaker and move the compressor back to its original location.

STILL, TRIPPING BREAKER?

Your air compressor is tripping the breaker due to untenable current demands that exceed the breaker’s capacity. Several factors can cause your compressor to pull too much power, but we will not waste time testing the compressor. If we determine it is the compressor, It’s new; bring it back.

Before resetting the breaker, find the amp rating on the compressor, be sure that the breaker is large enough to handle all the appliances and tools on that circuit. Take this time to unplug all other devices or tools that may be causing a draw on that circuit. Inspect the outlet that the compressor is now using. Is it lose, or has any signs of overheating? Replace the outlet or repair before going on to the next step.

How to test an unloader valve on an air compressor

To see if a failed unloader valve is the root of the problem, take the following steps:

- Unplug your air compressor

- Open the tank drain and let all pressurized air escape out of the tank

- Plug the air compressor back in

- Turn the air compressor switch to “ON,” restarting your air compressor. If the compressor starts, let the system fill.

- if the compressor still will not start inspect the pump.

- Once the compressor turns off, bleed some air until the motor starts. Replace the valve if the breaker trips while attempting to turn on with a full tank. The cause was the valve not releasing pressure from the cylinder head.

Inspecting an air compressors pump for mechanical concerns

To see if a failed pump is the root of the problem, take the following steps:

- unplug the compressor

- remove the cover plate or belt guard

- turn the pump by hand it should spin freely

If the pump is locked or hard to turn, It time to replace the pump

If the pump turns freely its time to test the electrical circuit.

Disclaimer: Self-diagnosing air compressor concerns may not be a simple problem. If you are not familiar with electric motors or circuitry, then you may need to take your air compressor into a shop to have a load test performed and diagnosed. Performing electrical tests is hazardous and should only be performed by a professional.

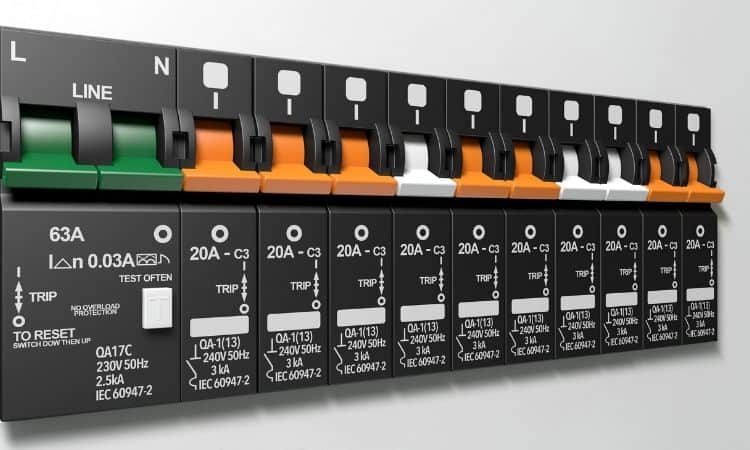

Measuring the amps that your air compressor produces while in use can be done one of three ways at the breaker box, exposing the wires at the compressor or using a splitter between the outlet and the cord of the compressor.

Click the link below to skip you down the page that best fits your situation:

My compressor is:

- 220volt single-phase or 220volt three -phase

How to Measure amperage on an air compressor. 110-volt A/C

Note: The compressor should be almost full of air to represent a heavier load on the motor on start and run.

plugging in a splitter into the outlet then plugging the compressor’s cord into the splitter is much like using an extension cord is the easiest way to test amperage.

————————-video————————————–

- measuring the amperage at the breaker box,

Safety glasses! Open the breaker box and turn off the main breaker,

reset the breaker to the compressor and then shut it off, remove the panel to expose the wires and breakers

place amp meter around the load wire, let some air out of the compressor so when you flip the breaker, the compressor turns on.

Watch the meter at start-up and while running.

Was the amperage on start-up and running lower than that of the manufacturer specifications?

2.measuring the amperage draw with an outlet splitter or inline wattage meter. If You have this splitter, it makes life a whole lot simpler. Unplug the air compressor, plug the splitter into the wall plug in the compressor to the splitter. Clip your meter on the splitter. You are ready to start the air compressor. measure the amps at start-up and while running

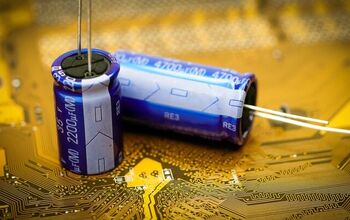

3.Measuring the amperage draw on the air compressor is my last option. The only reason I sometimes measure amperage this way is I suspect the capacitor, and a quick visual inspection may reveal it needs replacing. All air compressors are different, and the manufacturer uses as little wire as possible, making it sometimes challenging to expose and separate wires. Once you have gotten a location to clamp the meter. Start the compressor and watch the amps at start-up and while running.

Was the amperage on start-up and running lower than that of the manufacturer specifications?

How to measure amperage on an air compressor. 220-volt A/C

Safety first! Unplug or turn off the breaker, test to make sure power is off. Inspect all wire connections on the compressor. Removing cover plates to expose the wires will provide a place to use your amp meter.

I always recommend measuring 220 Amperage at the Breaker box. All connections, including the ones at the breaker, need an inspection.

220-volt has one common or neutral lead and two load wires measuring 110 volts. It is also possible it will have a ground wire. Place the amp meter around one of the two load wires. Start the compressor and let it run until it shuts off.

Note the amperage. Move your meter to the second load wire.

Bleed air from the system until the compressor starts and repeat the procedure.

If you are dealing with a new compressor and producing more amps than the manufacturer’s specifications, return it to the store. Brandnew compressor failure is more common than you would think.

Share this post:

(yes)If you Verified that the amperage draw is lower than the factory specifications and that of the breaker. The tripped breaker may be old and worn. Is it Possible to move the compressor to another circuit with the same amperage rating? Cycle the compressor on that circuit if there is no problem with that breaker. I would recommend replacing the worn breaker.

(no) A faulty capacitor is the most common cause for compressor tripping a breaker. Some compressors have two capacitors, and some have only one.

How to test an air compressor capacitor. with video

Safety First: Wear safety glasses disconnect power, and make sure power is not present.

Remove the cover to the capacitors. One capacitor will be the start capacitor. The other will be the run capacitor. Ratings and percentages are printed on the side of all capacitors. If it is not legible, there will be no way to test the capacitor. I usually replace capacitors that look distorted in any way, and capacitors are cheap enough that the cost is negligible compared to labor or a comeback.

——————————-pic————————————

Caution: A Capacitor can store a deadly D/C discharge!

With an isolated Scew driver, touch the top leads together on the capacitors. Discharging them eliminates the chance for shock.

Now that it is safe to handle the capacitors, remove them and look at the side of the capacitor; take note of the micro-farad range. The format will read something like(540-630µf) or (64µf + – 6%) but not those exact numbers, and This micro-farad range is the tolerance the motor needs to start and run under random loads generated by the compressor. In the first example (540-630µf), when testing the capacitors, the micro-farad range should fall between those readings. In the second example (64µf + – 6%), you must first do some math. 64×0.06=3.84 round up to the next highest round number equals 4.0 64 minus four equals 60 and 64 plus 4 equals 68

in this example, the capacitors range is between 60µf and 68µf.

Set your meter to this symbol -)|- or the µf. Connect the leads and measure the micro-farads. If the reading falls between the variance, the capacitor is good. In this example, the reading reads 61.2 µf the capacitor is within tolerance. And we would move on to the next step or the next capacitor. Replace the capacitor if it is out of range.

Is your air compressor the cause of your breaker tripping #weakbreaker

If you plugged the compressor into another outlet and the breaker did not trip, or you measured the amperage draw during use and the beakers ratings are above that witch the compressor is drawing, chances are the breaker is weak or there is a loose wire in that circuit. inspect the circuit for loose wires and replace the weak breaker.

Recent Posts

What Size Generator Do You Need to Run a Compressor?

If you need to run an electric air compressor in a location without an electrical outlet, you will need to have a generator accessible. Many job sites will require generators to power various tools...

How To Maintain And Service An Air Compressor: 18 Steps

Maintaining and servicing your air compressor properly is mission-critical for getting the most out of your air compressor. Compressed air is the lifeblood of many garage operations. How do I...

10 Reasons Why Your Air Compressor Keeps Tripping the Breaker

Few things are as frustrating as trying to use your air compressor only to have your circuit breaker trip – especially if it happens over and over again. To make matters worse, there are numerous possible causes, many of which can be difficult to diagnose. So this article will cover the many possible reasons your air compressor is tripping your circuit breaker, how to diagnose them, and what to do about them.

Table of Contents

A word on circuit breakers, immediate or delayed breaker trip, reason #1 your circuit is overloaded, reason #2 faulty circuit breaker or wiring issue, reason #3 short-circuit/failed capacitor/loose wiring in compressor, reason #4 dirty air filter or cooling components, reason #5 low oil/too much oil, reason #6 extension cord/power strip, reason #7 clogged cylinder, reason #8 damaged/improperly tensioned belt, reason #9 failed unloader valve or check valve, reason #10 faulty pressure switch, air compressor keeps tripping breaker conclusion, air compressor tripping breaker faq’s.

A circuit breaker is a switch designed to protect an electrical circuit (and the devices drawing power from it) from damage due to faults, shorts, or excessive current. They are located in your electrical distribution board (aka breaker box). When an electrical anomaly or overload is detected, the breaker will automatically “trip,” cutting off power to the circuit.

This gives you some idea of what’s going on when your air compressor trips the breaker – it’s usually due to an overload or electrical fault of some kind.

The first thing to keep in mind when troubleshooting a circuit breaker trip is when the breaker trips. Does it happen as soon as you turn it on or after it’s been running for a few seconds or more? The answer may point you in the direction of the root cause. That being said, some issues may cause either an immediate or delayed trip.

With that in mind, we’ll examine the possible causes in each scenario separately.

Air Compressor Trips The Breaker As Soon As It Starts

First, let’s look at what might cause your air compressor to trip the breaker immediately on startup. ( Note: this means when you initially turn it on, not when the pump kicks back on automatically during use – we’ll explore that scenario in the next section. )

Before looking at the air compressor itself, it’s best to rule out issues with your circuit. One of the most common causes of a tripped circuit breaker is a simple overload of the circuit. If you have multiple devices plugged into the same circuit, turning on your air compressor may simply put it over the edge – air compressors tend to draw a lot of power when the motor starts up. This issue may not always occur immediately on startup and may be accompanied by flickering/dimming lights.

Solution: Find out what other appliances or lights are on the same circuit and try unplugging other devices or plugging your compressor into another circuit with fewer (or no) other devices or lights connected to it – the closer to the breaker box, the better. If this solves the problem, the likely cause was an overloaded circuit.

The issue may also be with the breaker itself or a wiring issue somewhere else in the circuit. Breakers can wear out over time, so if you have very old breakers, this may be the issue. When a circuit breaker trips it can be from a loose or damaged wire, whether in the breaker box, outlet, or compressor power cord – or anywhere in between. A damaged extension cord may also be to blame (more on extension cords later).

Solution: Inspect visible cords for damage. If using an extension cord, try plugging directly into the wall instead; if the compressor power cord is damaged, you may need to take it to a professional for repairs. Test the circuit for continuity using a multimeter, or replace the breaker. This can be dangerous, so if you’re not comfortable and familiar with electrical work, don’t hesitate to hire an electrician.

If the circuits are fine and aren’t being overloaded, you may have a short in your compressor. This can be caused by a loose electrical connection, failed capacitor , or shorted motor windings (the coiled copper wires on a motor). Any of these issues can create an overdraw of amps, which will cause the breaker to trip.

Solution: With the compressor turned off and unplugged, check all electrical connections in the compressor head and tighten if necessary (your user manual should have instructions on how to do this). If this doesn’t solve the problem, you’ll have to test the motor windings and capacitor(s) to ensure they’re working properly. Again, unless you have experience with this, you’re probably better off taking it to a motor/compressor repair specialist to have this done.

In some cases, the motor or pump may simply be on its last leg, particularly if it’s very old. If so, you’ll likely be better off replacing the whole compressor.

Air Compressor Trips Breaker After Running for a Few Seconds (Or Longer)

It’s typically more common for an air compressor to trip the breaker after running for a short time or as the motor kicks on a second time to maintain pressure in the air tank. Let’s look at the possible causes of this.

If your compressor’s air intake filter is clogged with dirt and dust, it can strain the motor, causing it to draw more amperage than normal. If this excess power draw exceeds the breaker’s capacity, it will trip the breaker. Similarly, if the cooling fan intake grate or any other air pathways are clogged with gunk, the motor may overheat and cause the breaker to trip.

Solution: Clean or replace the air intake filter. Clean any other air pathways or cooling apparatus such as intake vents and cooling fins (compressed air and a microfiber cloth work well). Run the compressor again to make sure the problem is solved.

If your compressor is oil-lubricated, make sure it has the correct amount of oil in it. Too much or not enough oil can both cause the pump to struggle and overdraw power, resulting in our air compressor tripping the breaker

Solution: Check the oil level to ensure that it’s right where it should be according to the instructions in your user manual. Add or drain oil accordingly and try to run it again. If oil has entered your air chamber you may need to wait a day or so to let it drain back down into the sump.

Air compressors and extension cords don’t get along very well. Most extension cords aren’t rated for the amperage draw of compressor motors, which means the motor will be underpowered. This can cause the motor to overheat and trip the breaker. The same goes for power strips – and if several devices are plugging into the same strip, it can overload the circuit.

Solution: Plug the air compressor directly into a wall outlet or use an extension cord that’s rated for your compressor’s amperage (and the shorter, the better). In general, it’s always better to use a longer air hose instead of an extension cord.

If one or more of the pump cylinders has become contaminated with grit or rust, the piston(s) may not be moving freely, which can result in overheating or overdrawing of power. This can also occur with rotary screw-style compressors.

Solution: If possible, try to crank the motor drive by hand (with the unit unplugged). If it’s stiff or stubborn, the issue may be a clogged or corroded cylinder or mechanical element inside the pump. You’ll likely need to have this repaired by a professional. In some cases, you may need to replace the pump, compressor head, or entire compressor.

If your compressor uses a belt drive system, the issue may simply be that the belt is worn out or not tensioned correctly and is putting undue strain on the motor.

Solution: Inspect the belt for wear and tear; check for proper tension. Replace or re-tension the belt per your user manual’s instructions.

An unloader valve is a crucial component of an air compressor. When the tank reaches its pressure limit and the pump stops, the unloader valve releases any air trapped in the air chamber above the piston. If this valve malfunctions, the air will remain trapped and increase the load on the motor when it restarts to maintain tank pressure. This increased load can cause a spike in amperage draw and trip the breaker.

Similarly, compressors have a check valve that prevents air in the tank from flowing back into the air chamber. If this malfunctions (stays open), air from the tank will reverse course into the air chamber and overload the piston – again, possibly causing a tripped breaker.

Solution: Unplug your compressor and drain all of the air out of the tank. Then, plug it back in and turn it on with an empty tank. If the breaker trips while the tank is filling, it’s likely the check valve. If it doesn’t trip until the pump kicks on a second time (to maintain tank pressure), it’s most likely the unloader valve. In either case, the solution is to replace the valve in question.

If the breaker trips as the pump restarts to maintain tank pressure, another possible cause is a faulty pressure switch. When the tank is drained to a certain level, the pressure switch sends a signal to the motor, telling it to kick back on and pump more air into the tank.

If the contact terminals inside the pressure switch are worn or loose, it may create a short-circuit that trips the breaker.

Solution: Unplug the compressor and drain the air tank completely. Remove the cover on the pressure switch to expose its internal components (be very careful – you’ll be exposing live contact terminals that can shock you). Plug the compressor back in and turn it on, keeping an eye on the terminals. If you see any arcing or sparks, you have a faulty pressure switch. In this case, simply replace the pressure switch.

As you can see, there are numerous reasons your air compressor might be tripping the breaker. But with the help of this guide, you should be able to solve the problem with a little investigation and experimentation. However, always follow the safety precautions detailed in your compressor’s user manual and never attempt tests or repairs that you’re not comfortable with – especially where electrical components are concerned.

Can a bad compressor trip a breaker?

A bad compressor can trip your breaker. One that has trouble starting will pull more electricity than normal. And sometimes more than the breaker can handle. Which in turn would trip your breaker.

What is a common problem fault on an air compressor?

A few of the most common problems on air compressors are broken parts, oil leaks and air leaks. Each of these may cause your compressor to stop running or to not be able to start.

How do I stop my air compressor from tripping the breaker?

The first thing to check when trying to stop your air compressor from tripping the breaker is if the circuit you are using has enough amps to handle the compressor. If it does not have enough, move it to a dedicated circuit large enough to handle the draw your compressor is pulling.

Can An Air Compressor Be Laid Down or Stored on Its Side?

Air compressor types compared (pancake, hotdog, twin stack, vertical).

Galvin Power is reader-supported. When you buy via our links, we may earn a commission at no cost to you. Learn more

Why Does My Air Compressor Keep Tripping the Breaker?

Written by Edwin Jones / Fact checked by Andrew Wright

Does your air compressor circuit breaker trip every time you turn it on? Do you want to know how to stop air compressor from tripping breaker?

There are many factors why your air compressor trips your breaker. Additionally, each factor that affects the air compressor also has different types of solutions. So to fix this, you need to understand some of the problems it may encounter, thus causing the tripping.

Read on to find out the answer to “why does my air compressor keep tripping the breaker?” and how you can troubleshoot it.

Table of Contents

1. Shorted Air Compressor

2. damaged or shorted wire, 3. high power draw during start-up, 4. clogged condenser coil, 5. not enough or too much freon, 6. damaged condenser motor, 7. damaged contactor, 8. dirty air filter, 9. grounded disconnect switch, 10. faulty circuit breaker, possible factors.

Troubleshooting an air conditioning compressor can be challenging to do so. You need to trace the source of the problem, which is mainly under the purview of professionals. However, even DIYers can learn a thing or two to do their own checks.

Safety first: Before starting with your inspection, take precautions, especially when working with electricity. It’s best to disconnect the airconditioner’s main power before doing anything.

To give you an idea about the factors that affect your air conditioning compressor and breaker, these are some common problems that you might encounter. There are also included tips that can help you repair it quickly and easily. But if you’re not sure of what you’re doing, leave it to the professionals!

The most common reason for circuit breaker trips is a shorted air compressor. Sometimes, the air compressor trips breaker immediately, but sometimes it makes a noise for a moment before it trips its dedicated breaker.

Check the line and terminal of the air compressor with your multimeter. However, to test if the real short is your compressor, disconnect it from the circuit then turn on the affected breaker. If the breaker does not trip, then the compressor is the problem. In that case, you need to find a professional to look at it.

Furthermore, here is a detailed guide about breaker size for air compressors if you needed!

There is the possibility that the wire insulation connecting the air compressor to the breaker might be damaged. It could be because of animal bites, like mice, or simply due to aging. If this happens, it may short if it accidentally contacts other cables.

You should check the air compressor’s cable, starting from the disconnect switch up to the circuit breaker panel. If you find a damaged wire, repair it using wire and terminal connectors. You can find a good pair in the top-rated wire connector article so you can find a suitable wire connector to help you with your repair.

If your air compressor tripping breaker on startup, or if your lights dim or fluctuate for a few seconds every time you turn it on, it means that it has a high power draw. This high power draw might exceed your circuit breaker’s capacity, leading to a trip.

The best thing you can do about this problem is install a hard start kit containing a relay and a hard start capacitor. It can help drop the amp requirement by up to 50% for every startup. Check this guide to know how many amps an air compressor uses!

A clogged condenser coil can also cause an increase in amp requirements. If the air that goes to the air compressor is blocked by too much dirt, the fan will have to work harder, increasing its power draw.

To clean it, spray the coil with water using a water hose from the inside out. However, be careful while doing this, as too much force from your pressurized hose might damage the coils.

Freon levels may also be a reason your circuit breaker trips. When the freon in your air compressor does not match the manufacturer’s requirement, this can cause the unit to malfunction, therefore causing the trip. Unfortunately, you need a technician to check it and see if it’s the actual cause of your issues.

If your air compressor runs slow then trips breaker, check your condenser fan if it’s stuck or doesn’t rotate as fast. That could mean your condenser motor is damaged. This is because the fan draws a lot of power to cool your unit, which it doesn’t do well because of the damage.

A contactor is the one that controls the voltage of your air compressor. If the voltage is uneven for both terminals, it may result in tripping your circuit breaker. Test the voltage with a multimeter to see if you get voltage fluctuations. However, be careful during your testing as you’re dealing with live power.

A dirty air filter can also cause breaker trips. Like a dirty condenser coil, a dirty air filter can reduce airflow, thus requiring the fan to work harder.

Furthermore, the air filter prevents dirt from coming into the air pump. If it’s too dirty, it could fail and let contaminants into the pump itself, leading to expensive repairs. Change your air filter when you see that it is dirty.

A grounded disconnect switch may lead to a short circuit. It is also dangerous as it’s typically attached to the metal casing, thereby increasing the risk of electrocution. Regularly check the disconnect switch terminals and replace them immediately if you see any damage, like scorch marks.

If you’ve checked all the factors above and your compressor keeps tripping breaker, you may have a faulty circuit breaker. Call a professional electrician to check if your breaker is defective.

However, if you also see some scorch marks in your circuit breaker, immediately replace your breaker before it gets worse.

Note: Before troubleshooting your equipment, turn off your circuit breaker or pull out your disconnect switch. It ensures that no current flows into your air compressor line and keeps you safe from electrocution. You could also watch this video by Word of Advice TV so you can have a better idea of how to troubleshoot your air compressor.

All of the factors discussed above are some of the most common reasons air compressors cause breaker trips. If you’re experiencing the same problem, you can go through them one by one and see which one affects your unit. Still, if you’re unsure of what you’re doing, it’s best to call a professional electrician.

That way, you and your property can remain safe.

So, did you find the answer to why does my air compressor keep tripping the breaker? If you have additional questions regarding your air compressor unit, leave them in the comments section below.

I am Edwin Jones, in charge of designing content for Galvinpower. I aspire to use my experiences in marketing to create reliable and necessary information to help our readers. It has been fun to work with Andrew and apply his incredible knowledge to our content.

Air Compressor Troubleshooting Chart, Guide And PDF

Air compressors can occasionally run into issues that affect their performance. Troubleshooting these problems can save you time and money, and ensure your air compressor runs efficiently.

The process of troubleshooting an air compressor involves a systematic examination of the device to diagnose any issues related to its operation.

In this guide, we will share a complete air compressor troubleshooting chart, so you can quickly diagnose and fix any problems with your air compressor.

4. Check valves and gaskets:

If your air compressor isn’t producing enough air pressure, the first thing to check is the intake valve. If the intake valve has become clogged or damaged, it can cause a decrease in air pressure and performance.

Air Compressor Troubleshooting Topics:

– Air Compressor Troubleshooting Chart – Air Compressor Troubleshooting PDF – How Do I Troubleshoot My Air Compressor? – What Is The Common Failure In Compressor? – How Can I Make My Air Compressor More Efficient? – What Is The Best Way To Maintain An Air Compressor? – What Causes An Air Compressor To Stop Working? – What Causes An Air Compressor To Overheat? – What Are The Failures Of Air Compressor? – What Are Some Tips For Troubleshooting Air Compressor Problems? – Frequently Asked Questions – Final Words

Air Compressor Troubleshooting Chart

This guide to air compressor troubleshooting and maintenance should help you keep your system in top-notch condition.

However, if any issues arise that are too complex for you to handle on your own, it’s best to contact a professional for help.

Experienced technicians can quickly identify the problem and provide assistance with repairs or maintenance, ensuring that your air compressor is running smoothly and efficiently.

- How To Make A Confetti Cannon With An Air Compressor - December 4, 2022

- How To Keep Air Compressor From Freezing - December 3, 2022

- How To Install Oil Water Separator On Air Compressor - December 2, 2022

About Ivan Sanchez

Ivan Sanchez is a passionate blogger, traveler and certified Mechanic and moreover owns a Mechanic Shop in Norway too. He loves Painting Cars, Fixing them and a lot more. His father had a shop too where he used to sell Air Compressors, that's where Ivan learned about it and now reviewing some top-notch air compressors through this blog for you.

- Account Settings

Home Services

- Home Security

- Pest Control

- Living Room

- Other Rooms

- Home Improvement

- Cost Guides

- Floor Plans

Housekeeping

- Cleaning Tips

- Organization

- Popular Brands

- Sizes & Dimensions

Smart Living

- Dangerous Areas

- Safest Areas

- Most Affordable Areas

Top stories

Air Compressor Keeps Tripping Reset? (We Have a Fix!)

There is nothing quite as frustrating as your equipment quitting while you’re trying to complete a project. Have you ever been working and suddenly your air compressor trips to reset? Before calling it quits yourself and buying a new air compressor, there are a few things to check that might solve the problem.

If your air compressor keeps tripping reset, it’s doing so because it’s overheating. This might be because your power supply is not large enough to power the compressor. It might also be that the compressor is overheating from running for too long. Lastly, the centrifugal switch may not be functioning properly.

Do You Need Appliance Repair Services?

Get free, zero-commitment quotes from pro contractors near you.

A Reset Button’s Purpose

A reset button on an air compression is also known as a thermal cut or safety switch. It can be located on the end or the side of your compressor. In some cases, it’s located inside the wiring of the motor.

The reset button is there for your safety. Its main purpose is to automatically turn off the air compressor’s power when it overheats. If a compressor were to overheat without the presence of a reset button, the motor would be damaged. If your air compressor is tripping, it’s because it’s too hot.

Air Compressors

Using a gas engine or an electric motor as its source of power, an air compressor continuously sucks volumes of air from the atmosphere. It then compresses or squeezes that air into a tight space in order to make the volume smaller and increase its pressure . The high-pressure air is moved to a receiving tank which then powers the equipment.

Three Basic Types

The three basic types of air compressors are as follows:

- A reciprocating compressor has a cylinder with a piston inside which squeezes the air.

- A rotary screw compressor compresses the air with a spinning spiral screw of steadily diminishing volume.

- A centrifugal compressor has an impeller that rotates. The impeller transfers momentum to the air which then compresses it.

Any one of these types of compressors may trip your reset button if the power supply isn’t large enough , the compressor has been running for too long, or the centrifugal switch is getting stuck.

Not Enough Power

If you’re powering your air compressor with an extension cord or power bar, therein lies your problem. The power bar or extension cord may be too small to allow the proper flow of power.

By restricting the power through a smaller wire, the compressor motor can’t get a sufficient amount. This causes the motor to overheat which causes the thermal cut out to shut it down.

What’s the Fix?

Make sure your compressor is plugged directly into the wall outlet. A power outlet of 20 amps or more is best.

Running the Compressor Too Long

A compressor duty cycle is the length of time pressurized air can be delivered by the compressor. Typically, a duty cycle is between 10-15 minutes. If you run the compressor longer than the duty cycle allows, the compressor will overheat and trip to reset.

It’s likely that you will need to use your air compressor for longer than 15 minutes at a time. If that’s the case, you’ll have to take breaks in between uses. Run it for 10 minutes, and then, let it sit for just as long before running it again. This allows the engine enough time to cool so it won’t overheat too quickly during your next use.

Sticking Centrifugal Switches

The majority of air compressors have what is called a centrifugal switch. The centrifugal force caused by a rotating shaft (usually a gas engine or electric motor) activates the centrifugal switch.

If you think of it in terms of a car, the centrifugal switch is like first gear. It energizes the start-up windings. Once the compressor motor reaches ¾ of its RPM, it switches gears from the motor windings to the run windings.

Over time, the centrifugal switch can shift out of adjustment, causing it to get stuck in one position. If the centrifugal switch gets stuck in the open position, the windings won’t shift properly. The start windings can’t withstand the heat of the compressor’s full RPM, which will cause the compressor to overheat.

Depending on your comfort level and knowledge of centrifugal switches, you can adjust it yourself or replace it.

First, you want to make sure the points on the contact plate are in the open position. If they’re not, bend the circular spring flat so the points are no longer in contact. If the points are welded shut, then the contact plate needs to be replaced.

If there is light pitting on the surface of the points, you can sand them gently with 400 grit sandpaper. Larger deformities will create an unusable condition, so the contact plate must be replaced.

Tripping the Circuit Breaker

Occasionally, the problem may be bigger than the compressor itself tripping. What happens if you reset your air compressor only to trip your circuit breaker? There are a few things you can check to troubleshoot this problem.

Unloader Valve

If the unloader valve isn’t working, it might be the cause of the compressor’s malfunction. Sometimes, some of the compressed air gets trapped over the cylinder piston. That air adds to the load on the motor, potentially forcing it to pull too much power. This can trip a breaker or blow a fuse.

To find out if this is the issue, shut off the tank and unplug it. Then, drain all of the air from the tank. This will relieve the pistons of any excess pressure, allowing the tank to start up normally.

It’s important to occasionally inspect and clean the unloader valve to avoid trapping air over the pistons. If the problem continues, the unloader valve may need to be replaced.

Pressure Switch

It’s a little more unlikely, but a possibility is that your pressure switch shorted out. To find out if this is the issue, take the following steps:

- Unplug the compressor.

- Drain the tank and take off the cover.

- Restart the breaker system.

- Watch for signs of sparking or arcing. If you notice this, the pressure switch is your problem.

After many uses, motors get worn. Loose capacitor wires, worn windings, and other general wear in a motor can cause breakers and fuses to blow. If you’ve been running your compressor on the same motor for many years, it’s time to change it out.

Check out our guide: What Size Breaker For An Air Compressor?

Are Your Air Compressor Vents and Filters Clear?

Sometimes, when your air compressor cannot correctly vent itself, it can cause the compressor to continually reset so that the device does not become overheated and damaged. While running the air compressor for an extended time can certainly cause the unit to overheat, clogged vents and filters can also make the compressor overheat even more.

When the air vents and filters are clogged, the machine has to work harder than normal to pull in air from the outside. When the pump and motor are overworked, they can trigger the reset switch. Be sure always to clean the vents and filters on your air compressor and ensure there is no debris, hair, dust, or lint interfering with the machine’s ability to pull in outside air. Part of your routine maintenance on your air compressor should consist of routinely cleaning the vents.

Is Your Air Compressor Properly Maintained?

Sometimes, poor maintenance can cause your air compressor to reset continually. This fact is because there may be a mechanical issue within the air compressor that is causing the reset switch to trip before the tank is full.

To ensure that your air compressor is well maintained, you’ll want to perform a routine inspection about every six months to ensure that all the fittings, valves, and gaskets are in good working order. If your air compressor is continually resetting, you may have an issue with a broken pressure valve or possibly a broken gasket. Changing the valve or the gasket will help the compressor reset only when needed and help it maintain appropriate pressure.

Related Questions

There are quite a few reasons why an air compressor may trip to reset. However, you may still have more questions. Here are some questions other people asked related to air compressors and their functions.

Replace the check valve if it won’t start when there’s air in the tank. If the tank is empty of air, replace the pressure switch if it’s not engaging the pump motor. If the pump motor doesn’t start when activated by the pressure switch, the pump motor needs to be replaced.

Air compressors can fail for a number of reasons. If your air compressor is seeing a lot of use, the wear and tear on the unit could cause failure. The lifespan of a compressor varies from model to model, but an older one is more likely to fail simply because of its age. Not properly maintaining the compressor could also cause failure.

The time between oil changes varies with each compressor. Some require the oil to be changed more frequently.

For a rotary screw compressor, the general rule of thumb is to change the oil after 1,000-2,000 service hours.

For a reciprocating compressor, the general rule of thumb is to change the oil every 3 months.

This can be a sign of worn compressor cylinder seals. If the seals are worn, the air will bypass them into the sump instead of filling the tank. Air will then bleed from the oil fill cap.

Summing It Up

The reset feature on an air compressor is very important for your safety as well as the compressor’s motor. When the compressor overheats, the reset button will automatically shut it down to avoid hazardous heat levels.

To avoid tripping your air compressor to reset, make sure you’re taking breaks while using it to allow the compressor’s motor to cool. Check that the unit is plugged directly into the wall so that enough power can flow to the compressor. Inspect the centrifugal switch to ensure that it’s working properly and not getting stuck in one position.

It can be frustrating when the air compressor keeps tripping in the middle of a project, but remember, it’s for your protection. Hopefully, one of these solutions will fix the problem so that you can get back to using your air compressor peacefully.

Related Articles

- Is Your Refrigerator Compressor Hot? (Possible Causes & Fixes)

- Air Compressor Pressure Relief Valve Keeps Opening? (Fix It Now!)

Brigid Levi is a wife, mother, and freelance writer who enjoys a good DIY project and creating beautiful spaces within her home. From cleaning and organization hacks to home decor ideas, she loves helping people in their quest to turn a house into a home. Her hobbies include pretending to be Joanna Gaines while updating her home with her husband and performing in local theater productions.

More by Brigid Levi

Best Bushes And Hedges To Plant For Stunning Fall Colors

Popular articles.

Ways To Store Luggage So It Doesn't Take Up A Lot Of Space

How To Avoid Real Estate Scams

How To Tell If An HVAC Contractor Is Legitimate

Why Is My Fish Tank Losing Water So Fast?

What To Do When Your Movers Work Slowly

You may also be interested in.

ReliaBilt Door Review: Possibly The Best Patio Sliding Doors?

Sanded Vs. Unsanded Caulk: Which One to Use in Your Tiling Job?

Toilet Flapper Closes Too Soon? (We Have Ways to Fix It)

How Much Does Costco Flooring Cost?

![air compressor trips breaker while running Finishing Basement Without Permit [Is It Really Illegal?]](https://cdn-fastly.upgradedhome.com/media/2023/07/31/9070078/finishing-basement-without-permit-is-it-really-illegal.jpg?size=350x220)

Finishing Basement Without Permit [Is It Really Illegal?]

8 Types of Outdoor Faucets (for Residential Use)

How To Unclog A Refrigerator Drain Tube (Quickly & Easily!)

What Are the Parts of a Sink? (with Detailed Diagram)

Honeywell Thermostat Blinking "Cool On"? (Here's Why!)

17 Types of Stucco (Various Finishes & Textures)

How To Report A House That Should Be Condemned (It's Super Easy!)

How To Bypass The Lid Lock On My Washing Machine (Do This!)

Why Is My Smoke Detector Blinking Red? (Find Out Now!)

The 15 Most Dangerous Neighborhoods In Las Vegas: 2023's Ultimate List

Contractor Didn't Pull A Permit? (Here's What You Can Do)

Can You Replace A Capacitor With Higher UF? (Find Out Now!)

How Much Does Instacart Cost? (Membership, Fees, Tips & More)

How Should I Set My Thermostat When I Go On Vacation

Solving the dilemma: why is my air compressor keeps tripping reset?

Are you having trouble with your air compressor? Is it tripping when you turn it on, or every few minutes after running for a certain period?

We’ve all been there – it’s a frustrating experience and can be costly! But don’t worry, let us help you get to the bottom of why your air compressor keeps tripping and what you should do to reset the problem.

Several causes may lead to this issue, such as overloading, improper installation, improper wiring, insufficient power supply, etc. It’s important to run through each potential cause and make sure that you take into account all potential variables to find a solution.

In this article, we’ll discuss the various causes of air compressor breaker tripping and how to combat the problem so that you can use your air compressor without any further issues.

So keep reading if you want to get back up and running in no time!

- 1 What is an air compressor reset?

- 2 Common causes of air compressor tripping

- 3 Troubleshooting tips for air compressors

- 4 How to fix a faulty pressure switch

- 5 How to test your air compressor

- 6 Tips for recognizing and preventing potential issues

- 7 Air compressor keeps tripping reset? (We have a fix!)

- 8 Is your air compressor properly maintained?

- 9 Where is the reset button & what does it look like?

- 10 Conclusion

- 11.1 What could be causing my air compressor to trip circuit breakers?

- 11.2 What should I check if my air compressor trips the breaker?

- 11.3 What safety measures should I take when dealing with electric issues?

- 11.4 Air compressor keeps tripping reset? (We have a fix!)

- 11.5 Are your air compressor vents and filters clear?

- 11.6 Is your air compressor properly maintained?

- 11.7 Where is the reset button & what does it look like?

What is an air compressor reset?

If you’re wondering why your air compressor keeps resetting, first, you’ll need to understand what an air compressor safety switch is. In short, it’s a safety feature designed to protect the compressor in the event of an overload or power surge.

When this happens, the air compressor reset button can be used to switch off the power supply and allow the motor to cool down before being restarted.

The problem with this is, while the safety switch can prevent further damage to the motor and compressor, it won’t fix the underlying issue that caused the reset in the first place. That’s why it’s important to identify what is causing your air compressor to trip or reset to avoid future trips or resets.

The major causes of air compressors tripping can include:

- Not enough airflow (blocked filters)

- Not enough oil levels

- A motor fault or freeze up

- An electrical surge or overload of current

What’s the purpose of the air compressor reset button ?

Let us start by talking about the air compressor reset button. A thermal overload switch or thermal cutout switch is a device that automatically shuts off the air compressor’s power when it overheats.

The air compressor reset button is usually located at the back of the compressor or in its electrical wiring. The air compressor reset button protects the engine from being destroyed in case it becomes overloaded. It also causes air compressors to stop snoozing when it gets hot.

Common causes of air compressor tripping

A motor issue might be one of the most frequent causes of your compressor’s recurrent trips. Usually, gas engine difficulties are brought on by a damaged fan, a loose electrical connection, or even a motor fault.

In some cases, you may need to completely replace the motor.

Tripping might also result from issues with the air compressor’s cooling system . Your machine may trip and shut off if it cannot properly cool itself. Low oil levels in your system or blocked filters obstructing airflow might be the reason for this.

If the unloader valve fails , part of the pressurized air in the tank may become trapped above the cylinder piston. The air then increases the total load on the motor, perhaps forcing it to draw too much power and blowing the fuse or tripping the breaker.

The duty cycle of a compressor is the amount of time the compressor can deliver compressed air. Normally, a duty cycle lasts between 10-15 minutes. If you run the compressor for a longer time than the duty cycle allows, it will overheat and trip to reset.

The duty cycle is vital, and it works on the premise that for every 10 minutes of work , you should have 10 minutes of rest . If you don’t have a user manual, you may find out the duty cycle of your compressor by getting in touch with the manufacturer.

Most air compressors include centrifugal switches . Centrifugal switch-driven motors activate the centrifuge. If one thinks about cars, then centrifugal switches are the same in first gear: it revs up the momentum of a startup.

After a compressor motor hits 34 rpm , the gear shift is made by the motor windings in the drive windings. Often the centrifugal switch is left out of the adjustment and can remain locked in one location. If a centrifugal switch remains open, the motor windings cannot properly move.

Over time, the centrifugal switch can shift out of adjustmen t, which causes sticking centrifugal switch.

If the centrifugal switch were to get stuck in an open position, then the windings won’t shift properly .

Finally, overloading your air compressor is a common reason it may be tripping on and off. If you’re running too many tools at once, or they require too much power at once, your machine may not be up to the task and trip out as a safety switch.

Troubleshooting tips for air compressors

When it comes to fixing the issue of why your air compressor keeps resetting, there are a few troubleshooting tips you can benefit from. To make sure you’re doing everything right here is what you should do:

- Unplug the air compressor power bar and make sure that it is turned off. Then, open up the unit and check for dirt and debris. Clean out any buildup found in the unit with a brush or compressed air canister.

- Test all connections. To check for problems with wiring or other connections inside the machine. If you find that any of them need to be replaced, you must do so as soon as possible to prevent further damage from occurring. It’s common for older air compressors to develop a tank check valve leak .

- Check the pressure switch for signs of wear or damage – replace it if necessary. You may also want to try to replace the broken pressure valve and use a multimeter to measure power to ensure it is adequate for your air compressor needs.

- Finally, if everything else fails, it may be time to call in a professional!

How to fix a faulty pressure switch

It could be something as simple as your broken pressure valve. A pressure switch’s job is to turn on and off the power supply to the electric motor, depending on the pressure in the air tank.

So, how can you tell if it’s your pressure switch causing this issue? Here are a few signs to look out for:

- Motor shutting off while running

- The motor won’t start

- Motor runs but no air is produced

- Intermittent on/off cycling of compressor motors

- Pressure gauge readings that don’t make sense

If you’re experiencing any of these problems with your air compressor, it’s time to check if it’s your centrifugal switch . Testing the switch is a simple process , and can save you from purchasing a new motor or paying for an expensive repair. All you need is a multimeter, which you can get from most hardware stores.

Here are the steps:

- Unplug the power bar and disconnect all wires from the centrifugal switch.

- Set your multimeter range to ohms —the symbol looks like a fishhook. Make sure not to touch any exposed metal parts or terminals during the test process!

- Place one probe of multimeter into each terminal of the centrifugal switch

- Check that there is continuity when it is in the “on” position and then again when it is in the “off” position (in other words, make sure that there are low resistance levels when switched “on” and higher levels when switched “off”)

How to test your air compressor

If you think you’ve done all the steps to make sure your air compressor doesn’t keep tripping, it might be time to run a few tests.

This will require unplugging all appliances and electronic devices from the power bar and the circuit breaker for the house or unit.

Check the pressure switch.

Isn’t it so frustrating when you have a fully loaded air tank, and you begin operating the air tool , and as the pressure starts to build, the air compressor suddenly trips the circuit breaker and the reset switch is good for absolutely nothing?

Make sure that your pressure switch is set to shift properly . The set pressure should not exceed the range of pressure values stated in the manual; otherwise, it could trip at low pressures.

If it is set too high, simply adjust the range accordingly and test it by running it until its peak pressure point, then resetting the switch.

Check for overheating.

Usually, a gas engine on your air compressor produces a certain amount of heat when running, so any higher than normal temperatures can cause it to overload and shut down.

The duty cycle is crucial, and it operates on the principle that if your compressor has a 50% duty cycle, you should take 10 minutes off for every 10 minutes of work.

To test this, feel around each part of the compressor to see if any spots feel abnormally hot . If so, this could be a sign that there is poor air circulation or something more serious is going on with your electric motor and compressor —it may be time to call a professional.

Test your amps.

You can alsogauge how well your air compressor performs by testing the amps on each component while running. This way, you can get an accurate reading of how much current your system is using and whether anything needs to be serviced or replaced altogether.

Tips for recognizing and preventing potential issues

If you’ve been having problems with your reset switch, then don’t worry — you’re not alone.

But to prevent future issues, it’s important to recognize potential issues before they turn into bigger issues.

Here are some great tips that can help you recognize and prevent potential air compressor issues:

- Check for voltage.

Check the power supply for any voltage problems from the power source, such as fluctuating current or voltage irregularities, which can cause tripping, surges, or spikes in power.

Rather than using an extension cord , plug your air compressor directly into a wall outlet. A power outlet of 20 amps or more is even better. In general, it’s always better to use a longer air hose instead of an extension cord .

- Adjust settings .

Adjusting settings on your air compressor can also help reduce the chances of tripping the reset switch.

If you have an adjustable centrifugal switch on your unit, adjust its settings accordingly to put less strain on the motor by reducing pressure levels when not in use.

Checking all centrifugal switch belts for proper tensioning is also important — too much tension puts more stress on your compressor and can lead to malfunctions.

Air compressor keeps tripping reset? (We have a fix!)

It’s incredibly frustrating when your air compressor keeps tripping reset, but we’ve got a fix for you.

Before anything else, take a look at your compressor settings. When it has been unplugged or left idle for too long, the pressure switch will be too low, meaning the motor won’t get the necessary air compressor power to start running.

In this case, you’ll want to adjust the centrifugal switch by following the manufacturer’s instructions.

Additionally, regular maintenance on your compressor can save you many headaches in the long run—things like changing out oil and checking the belt should be done at least once a year (or more often, depending on how much use it gets).

Are your air compressor vents and filters clear?

That’s an often overlooked reason why your air compressor might be tripping—but it’s worth checking out.

If your filters and vents are clogged, then it can cause the motor to overheat, ultimately leading to a trip-out. It’s important to be sure all filters, intake vents, and exhaust power outlets on the compressor are clean and that there’s plenty of ventilation around the machine.

If they’re blocked, air won’t move freely around the compressor motor and eventually, your compressor overheats and trips out.

If you find that cleaning the vents doesn’t work, then you’ll want to investigate installing an external fan to ensure steady airflow around the motor and keep it cool.

Is your air compressor properly maintained?

Finally, it’s important to check if your air compressor is properly maintained . Air compressors are machines and, like any machine, components can wear down over time. If you don’t do regular maintenance on your air compressor, it can cause it to trip more frequently than usual.

Some of the most common maintenance tasks include:

- Changing the oil

- Tightening electrical connections

- Checking the centrifugal switch settings

- Replacing air filters

- Inspecting hoses and piping for leaks or blockages

Doing these things can ensure that your air compressor will continue to work safely and efficiently long-term. If you’re not sure how to perform any of these tasks, a handyman or professional technician can help you out.

So if your air compressor keeps tripping reset, make sure it’s properly maintained before you call an expert!

Where is the reset button & what does it look like?

The reset switch is usually located on the side of the air compressor and is usually red or black. It’s typically marked with a warning sign or the word “reset” to distinguish it from other knobs and buttons.

That said, the place and appearance of the reset button can vary from model to model, so it’s important to make sure you’re looking in the right place.

To do this, check your user manual for specific instructions on resetting your compressor.

If you still can’t find it after that, don’t worry — there are other ways you can troubleshoot your compressor. When in doubt, always consider a certified technician to come and take a look at your equipment.

In conclusion, if you’re having any issues with your air compressor, the first step is to try to diagnose the issue. You might be able to solve the problem yourself, or it might require a repairman that relevant as well if you experience issues with a dehumidifier .

Additionally, it is significant to make sure that your air compressor is properly maintained , as this can also help minimize tripping problems.

Frequently asked questions

What could be causing my air compressor to trip circuit breakers.

There can be a few reasons why your air compressor causing to trip the circuit breaker. It could be caused by a faulty electric motor, overload, excess pressure in the tank, too many amps running through the system, or insufficient power supply .

What should I check if my air compressor trips the breaker?

The first thing to check is if there is any visible damage on the compressor motor, like burning or fraying wires. You should also inspect that all wiring connections are in order and there aren’t any loose wires that might cause an electrical circuit breaker to trip.

Additionally, check an unloader valve, which is a critical component of an air compressor. When the tank reaches its pressure limit and the pump stops, the unloader valve releases any air trapped in the air chamber above the piston.

What safety measures should I take when dealing with electric issues?

Always make sure you unplug the air compressor’s power source before attempting any repairs and wear protective gear like gloves when inspecting electric wiring connections.

The first step is to check for any blockages or kinks in the air hose. If there are none, then you should check the air filter for dirt and debris buildup. If this doesn’t solve the issue, try resetting the circuit breaker. If the problem persists, it may be time to call a professional for help.

Air compressor vents and filters should be regularly checked and cleared of any debris or blockages to ensure proper operation.

Properly maintaining an air compressor is essential for optimal performance , efficiency, and longevity. Regular maintenance can help prevent breakdowns, reduce energy costs, and extend the life of the compressor.

Additionally, properly maintained air compressors can provide reliable, consistent air pressure and air quality, ensuring that tools and equipment operate safely and efficiently.

The reset button on an air compressor is typically located near the motor or pressure switch . It is usually a red button with a small hole in the center.

Read More: Is Your Air Compressor Tripping the Breaker

Considering that most people continue to pay the masters in the service for a consultation, I decided to create my blog.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

Fix My Compressor

Compressor Trips The Breaker On Restart

You’ve got a full tank of air. The air tool ramps up nicely and is working well. Then, and as the pressure in the tank drops to the cut in pressure setting, rather than the compressor starting to rebuild the air in the tank, when it tries, the compressor trips the breaker on restart. If it’s a fuse in the circuit instead of a breaker, when attempting to restart, the compressor blows the fuse. The information on this page includes:

-what’s happening when the compressor trips the breaker or burns the fuse on restart?

-what needs to be checked on the air compressor when that happens?

-what are the compressor components involved and how to check them?

What’s happening when a compressor trips the breaker / fuse on restart?

When the air compressor tank is drained down to the cut in pressure level, the pressure switch reacts to the drop in tank pressure, it trips to “passing” (as in, the current now flows to the compressor motor) and the compressor should start and run until the compressor tank pressure has reached the normal cut out pressure setting, at which time the compressor should stop and wait for the tank air pressure to drop to the cut in pressure level again.

At the cut in pressure setting the the current will flow first through the pressure switch and then through the motor start circuit, and for a huge number of different makes and models of air compressor, the current then flows to a start capacitor.

If a particular compressor motor does not have a start capacitor, often that’s a small, sub-fractional motor, and there is sufficient current in the electricity flow to kick that motor into turning.

Larger compressor motors require a “kick start” to get going, as there is not enough power in the circuit to to feed what the compressor motor needs on start up, and that’s called the “inrush current”.

If for some reason the motor cannot start, it will continue to draw power, and may pull enough amperage to exceed the capacity of breaker or fuse and as a result the compressor trips the breaker or fuse on restart.

What are the things on the compressor to check when the air compressor trips the breaker or fuse on restart?

Did the unloader valve work sometimes the unloader valve fails, and as a result, some compressed air is trapped over the cylinder piston. that trapped air adds to the load the compressor motor experiences on start up, and that additional load may be enough to force the motor into pulling too many amps and popping the breaker, or blowing the fuse..

To test for this, unplug the compressor, open the tank drain and drain all the air out of the compressor tank (which you should do after every use of your air compressor as part of the regular preventive maintenance), plug the compressor back in and if your compressor has one, flip the ON/OFF switch to on.

If the compressor starts this time and the breaker doesn’t pop, that suggests that your air compressor unloader valve is not working properly, one of which made by Square-D is shown in the image above, and you need to either fix it or replace it. To be sure, shut off the compressor, drain the tank again, and try to restart it with an empty tank. If the compressor starts easily again, then it’s pretty much certain that it’s the air compressor unloader valve failure that is causing your air compressor to trip the breaker on restart.

Are you plugging the air compressor into a power bar or extension cord? Home use extension cords are notorious for throttling power, as is a power bar. You may be under powering your compressor motor, and the resulting overheated motor may be contributing to the breaker tripping when the compressor starts.

Leave the compressor to cool for 15 minutes or so, and then try plugging the air compressor power cord directly into a wall socket, preferably one that has a 20 amp breaker, and has no other electrical devices using power at the same time as the air compressor is trying to start.

If the compressor starts this time, and after you have used some air and the compressor successfully restarts when the tank pressure drops to the cut in pressure setting, then you’ve nailed down the problem.

As a general rule we suggest that you add air hose to get the compressed air to your work station as opposed to using an extension cord to move the compressor closer to where you want to use compressed air. Nothing gets damaged if it doesn’t get enough air through a long hose. On the other hand, electrical devices are overworked if their power supply isn’t up to what is required leading to electrical maintenance issues.

Is it the pressure switch itself that has failed? Less likely, but still possible, that your air compressor trips the breaker on restart can be cause by a pressure switch that has shorted out.

When the air pressure in the tank drops, a diaphragm inside the pressure switch moves, and ultimately, that moving diaphragm forces the points inside the pressure switch to touch, a circuit is made, and power flows to the compressor motor starting it, and driving the pump to pump more air into the compressor tank.

Turn off or unplug the compressor.

Drain the compressor tank and then close the drain.

With due regard to the presence of live terminals inside the pressure switch, pull the cover off, reset the breaker, and watch inside the pressure switch to see if there is any arcing or sparking when you turn the compressor back on.

Since the pressure switch points should already be touching with the absence of air in the tank, there should not be any arcs or sparks, and if there are, that’s a pretty good indication that you pressure switch may be the problem.

You will need to replace the pressure switch.

Has the compressor capacitor failed?

If the compressor has a start capacitor, or a start / run capacitor, or two capacitors, the failing of one may mean that the compressor will blow a fuse or circuit breaker when attempting to start.

This is what a typical motor capacitor will look like:

The correction of the problem of when the air compressor trips the breaker on restart becomes increasing complex once these earlier tests have been made. One of the more complex tests is that of testing the capacitors.

If useful for you, please follow this link to our page that describe what the capacitors are and about how to test them.

Compressor motor windings shorting? In our opinion the next component that will be suspect when the compressor trips the breaker on restart are the motor windings shorting, or any of the electrical connections inside the motor that may be shorting and the sudden flow of electricity to ground pulls too many amps.

If you have reached this state in your compressor problem diagnosis, and you are not skilled in electrical motors or electrical circuitry, we suggest that you get your compressor motor to an electrical motor shop for a load test to try and determine what, if any, part of the motor is shorting.

These are a few of the typical reasons why an air compressor trips the breaker on restart. If you have experience with other scenarios, why not share them with visitors using the comment box below? If you see a comment and you would like to add to it, please feel free.

It is always helpful if you identify the make and model of your air compressor in any post.

Related posts:

No related posts.

By Ashley Pearce

As a passionate manufacturing and mechanical engineer, I've had my fair share of run ins with air compressors and compressed air systems. With over a decade of experience in the industry, I have both a fresh perspective and time-served hands and mind to help you with your compressor problems (along with our able community!)

Hi, I have an old Husky Air Scout 1.5 gal 135 psi max air compressor that I bought from a friend for cheap. I have used the compressor maybe 25 – 30 times at 100 psi with no problem. I plug the compressor into a wall outlet connected to a 20 amp circuit breaker. last week when I tried to use it, it worked fine for the first 15 inch mower wheel. I shut it off after bleeding the air. (there is a bleeder valve on the front) . When I tried to turn it on again an hour later, It blew the fuse that was in a fuse case on the front. I went to the hardware store and bought a 4 pack of fuses. It blew all four (one at a time) as soon as I turned the compressor on. It never got a chance to compress any air. Put new fuse in. Turn on compressor. Blown fuse immediately. There is no circuit board that I can see. There is a pressure switch (120vac 10 A) in the unit. Can anyone tell me what might be happening?

Hi, is there someone that can help me It is model 919.176841 Craftsman 4hp 20 gallon horizontal air compressor. The problem is it will start and go up to proper tank pressure with no problem. But then if you use the air hose and the pressure drops to around 75, which is normal, it goes to start again, and it barely turns. If I leave it trying, it will kick out the reset on the motor. If I disconnect the big line that comes out of the compressor head, it starts fine. I took off the air filter, and it wasn’t that. I replaced the unloader valve at the switch on the smaller air line. Nothing changed. But, if I push down the little reed valves while it trys to restart, it restarts fine. I just hold down the reed valves with a small screwdriver just long enough for the compressor to get up to normal rpms. Then it runs fine. It will run all day long once it’s started. I used a blow gun attachment to keep bleeding off air pressure while it was running, and it keeps runnning fine and building pressure with no problems. ? I’m stumped here. Please help Thanks -Jim

I am facing the same problem 100 hp fini air compressor tripping the breaker . Checked the motor winding no shortage how can i check step by step found the exact problem

Hello, this website is really helpful! I have an Eagle Silent Series .75-HP 1-Gallon Hot Dog Air Compressor, and am having issues with the breaker tripping while the compressor is running. It happens very sporadically. Sometimes it occurs every few minutes, sometimes every few hours. I have replaced the capacitor on the compressor. From this page, it sounds like it may be an issue with the compressor being underpowered. Besides plugging in directly to an outlet, do you have any suggestions for remedying this issue?

It’s difficult to be certain what the issue may be, Tianna. For example, when the compressors is running, does it run for long periods at a time… hours instead of minutes? If so, could be that the motor is overheating due to it not having time to cool between uses. This relates back to the Duty Cycle, and if you commonly exceed that with a compressor, that’s how the motor reacts. This compressor has a 50% duty cycle, meaning that for every period of time – in 10 minute increments, not hours – the compressor must sit unrunning for an equivalent period of time for it to cool. Could this be the issue?

And if the compressor trips the breaker after it’s going/ pumping out air? Anything on the compressor that would caused that or is it just an overloaded circuit now? Thank you for your help.

Sorry, not clear. Are you saying that the breaker trips after the compressor has started, and is pumping air into the tank? If so, what pressure does it pop the breaker, please. And, what’s the make and model of yours? Thanks.

Hi There I have the Hitachi ED-12 compressor. I was having trouble with the compressor starting and getting up to speed. It would eventually blow a fuse.

I did what was suggested and opened the drain valves and it has no problem getting up to speed right away. I assume that means the capacitors are fine and from what I have read, you need to replace the “unloader valve”? I am not sure where that is in my unit?

Could you be referring to the non-return valve? Item #53 in the pic below? I see on a parts site it says to replace that if you are having these issues.

I got this unit for free and it has been great, I don’t use it that often, but like to have it for winterizing my pool shed and sprinkler system.

I appreciate all your feedback

Hi Chris. I’ve modified your post somewhat to remove many of the off-site links that didn’t really help.

First, you are referring to the EC12 compressor, yes?

You say “I did what was suggested and opened the drain valves and it has no problem getting up to speed right away. I assume that means the capacitors are fine and from what I have read, you need to replace the “unloader valve”? I am not sure where that is in my unit?”. Opening the drain valve removed over-piston air load, and emulates the function of the unloader valve. If opening the tank drain valve worked, the first check is the unloader valve. After the compressor gets going, close the tank drain, and let the air pressure build up to cut out. As the compressor stops on full pressure cut out, liste around the pressure switch (yours appears to have an internal unloader valve) to ensure that there is an quick burst of air from the pressure switch signifying that the compressor has unloaded.

If the compressor unloads, then it’s quite likely that the issue IS the start capacitor being weak.

You say “Could you be referring to the non-return valve? Item #53 in the pic below? I see on a parts site it says to replace that if you are having these issues.”, no, I am not. I am referring to the unloader valve that is part of the pressure switch.

Right, It does hit full pressure and will stop. I dont recall hearing a his release but will check again. Also, is there a “foot valve” that will keep the pressure in the cylinder head as well that might need to be replaced?

Also, can the unloader valve be serviced/cleaned and it looks like on my unit, I have to replace the whole apparatice that houses the valve? is that correct?

Remove the cover (carefully) of the pressure switch, empty the tank, start the compressor, close the tank drain, and monitor the unloader which is a part of the pressure switch on this compressor. If it works, check the start capacitor. See how here: http://fix-my-compressor.com/is-the-compressor-start-capacitor-working/

The “foot valve” you refer to is the tank check valve, and it’s in the fitting where the air line from the pump head reaches the tank. If air pressure stays in the tank after the compressor has stopped and unloaded, it is likely working fine.

i started it up again with an empty taNK. starts no problem and runs but dont shut down it gets to a point that it is working hard then stops and hums, full tank of air. so some pressure regulator switch is the issue for sure.

No, I don’t think so. Check the capacitor, Chris.

Fair enough, but how do I find a discontinued part? Can i just get a same or similar spec capacitor?

The photo shows a 40 micro-farad capacitor, and the voltage. It doesn’t show the spade or connector types on top. As long as you get a new cap with the same ratings, and it fits your compressor, it should work fine.

Okay, I pulled the caps. they seem fine. I was only able to test continuity and they seemed to be fine for continuity.

Here are some pictures. I don’t have a capacitor tester

http://fix-my-compressor.com/is-the-compressor-start-capacitor-working/

how do i find a replacement cap. without going to original OEM spec cap?

What size am I looking for? Granger.ca seems to have them in Canada/.

Hi Chris. Does this page not provide enough info: http://fix-my-compressor.com/finding-a-new-compressor-capacitor/

If not, add a comment. Thanks.

Hi there! Great website and very informative!

Ok I bought a used 20 Gallon Porter Cable C5510 air compressor for cheap. The guy said it runs but trips his breaker every once in awhile. I figure he probably had a weak breaker and I should be good. Got it super cheap so didn’t mind taking the gamble.

Ok. My setup is: – 15A outlet in garage with nothing else connected to it.

When i first install it it was working fine. It would pump up from empty to cut off and then turn on at cut in. Rarely it would trip my breaker.

Fast forward a few weeks, now it constantly trips the breaker.