Efficient and Reliable: The Power of Hot Surface Ignitors for Water Heaters

Water heaters play a crucial role in our daily lives, providing hot water for various purposes. Within these systems, the ignition process holds paramount importance, ensuring reliable and efficient operation.

In recent years, hot surface ignitors (HSIs) have gained popularity as a superior alternative to traditional ignition systems such as pilot lights and piezo ignition.

This article explores the advantages and disadvantages of hot surface ignitors, discussing their working principle, common problems and troubleshooting techniques, testing, replacing, and a comparison to other ignition systems.

Table of Contents

Hot Surface Ignitors for Water Heaters: Considerations and Benefits

What are hot surface ignitors, and how do they work.

Hot surface ignitors are heating elements specifically designed to initiate combustion in various heating systems, including gas water heaters .

They operate through a simple yet effective process. When the water heater calls for heat, the ignitor control module activates, providing electrical current to the silicon carbide or silicon nitride heating element.

The element heats up rapidly, reaching a temperature that can ignite the fuel gas directly upon contact. The gas valve opens, allowing the fuel to flow, and the hot surface ignitor ignites the gas, initiating the combustion process.

Are They Safe?

Hot surface ignitors incorporate safety features to prevent gas leaks and potential hazards. These safety measures often include flame sensing capabilities and safety shut-off mechanisms. The elements should be installed, operated, and maintained in accordance with safety guidelines and local building codes.

Many HSIs include a flame sensor as a safety measure. The flame sensor detects the presence of a flame once the gas ignites. If the flame sensor does not detect a flame within a specified timeframe, it signals the control module to shut off the gas supply, preventing the accumulation of unburned gas and potential hazards.

In addition to the flame sensor, modern water heaters often have safety mechanisms that shut off the gas supply if any abnormal conditions are detected. This can include excessive heat, flame failure , or other potential safety risks.

Common Problems and Troubleshooting Tips

While hot surface ignitors are generally reliable and widely used in gas water heaters, they can experience certain issues that may require attention or maintenance.

Here are some common problems and troubleshooting tips:

- Ignition failure : Check the power supply to ensure it is functioning properly. Inspect the ignitor for wear, cracks, or damage. Clean it to remove any debris. Verify the positioning of the part and ensure it is close to the burner assembly. Check the gas supply to ensure there is enough gas for ignition.

- Intermittent ignition : Inspect the wiring connections for any loose or damaged wires. Clean the ignitor and surrounding area to remove debris. Verify that the flame sensor is clean and properly positioned. Monitor the voltage supplied to this element and address any fluctuations or power supply issues.

- Uneven or delayed ignition : Inspect the ignitor for wear, cracks, or damage. Clean it to remove debris. Adjust the positioning of the ignitor to ensure proper alignment with the burner assembly. Check the gas pressure to ensure it is within the recommended range.

- Ignitor not heating : Check the electrical connections to ensure they are secure and undamaged. Verify the power supply to the ignitor. Test its resistance using a multimeter. If the reading is infinite, consider replacing it. If troubleshooting steps do not resolve the issue, consult a professional technician.

If you suspect that there is a problem, test the element.

How to Test a Hot Surface Ignitor

Testing a hot surface ignitor allows you to verify its functionality, diagnose heating system issues, and ensure safe operation. By conducting tests, potential problems can be identified early, preventing unexpected breakdowns. It is also a cost-effective troubleshooting step that helps pinpoint this element as the source of the problem. Additionally, testing helps determine if it needs replacement, saving time and effort on unnecessary troubleshooting steps.

To test a hot surface ignitor, follow these steps:

- Safety first : Prior to conducting any testing or inspection, ensure the power supply to the heating system is turned off to prevent accidents or electrical shocks.

- Access the ignitor : Locate the hot surface ignitor within your heating system. This may require removing a panel or access cover to reach this part.

- Resistance measurement : Using a multimeter set to resistance or ohms mode, you can test the electrical continuity of the ignitor. Remove it from the system and disconnect any wiring connections. Touch the multimeter probes to the two electrical terminals of the ignitor, ensuring a secure connection. A good silicon nitride hot surface ignitor should have a resistance reading between 30 to 75 ohms (depending on the manufacturer and model). If the measurement falls within this range, the ignitor is functioning properly. If the resistance reading exceeds 75 ohms, it indicates a failing or failed hot surface ignitor.

- Visual confirmation of glow : For additional confirmation, you can visually test the ignitor’s ability to glow when powered. Reconnect the ignitor to its wiring and restore power to the heating system. Observe it closely for a bright orange glow. A properly functioning ignitor should exhibit this glow. If there is no glow or only a faint glow, it suggests a problem with the element.

- Interpreting resistance readings : If the multimeter shows a reading of 0 or ∞ (infinity), or no reading at all, it signifies a broken resistance, indicating that the ignitor is faulty and needs to be replaced.

Things to Consider When Replacing a Hot Surface Ignitor

When replacing a hot surface ignitor, there are several important factors to consider to ensure a successful and safe replacement. Here are some key things to keep in mind:

- Compatibility : Ensure that the replacement ignitor is compatible with your water heater type and model. They come in various shapes, sizes, and electrical specifications, so it’s crucial to match the replacement with the original specifications to ensure proper fit and function.

- Type and material : Consider the type and material of the ignitor.

- Voltage and current rating : Verify that the replacement ignitor has the correct voltage and current rating. This information is usually provided on the part itself or in the system’s documentation. Using one with an incorrect voltage or current rating can lead to improper heating or even damage to the system.

- Quality and reliability : Choose a high-quality replacement element from a reputable manufacturer. Investing in a reliable and durable ignitor will ensure long-term performance and minimize the need for frequent replacements.

- Installation : Follow the manufacturer’s instructions and any applicable safety guidelines when installing or replacing one.

- Testing and verification : After installation, test the newly replaced ignitor to ensure it is functioning correctly. Observe the ignition sequence and check for the presence of a stable flame. Monitor the system for any abnormal behavior or issues that may arise after the replacement.

Replacement: Step-by-Step Instructions

However, please note that specific instructions may vary depending on your water heater type and model.

- Turn off the power : Before starting any work, ensure that the power to your heating system is turned off at the circuit breaker or main electrical panel.

- Locate the hot surface ignitor : The ignitor is usually located near the burner assembly. Refer to your heating system’s documentation or consult a professional if you’re having trouble finding it.

- Disconnect the electrical connections: Carefully disconnect the electrical connections to the ignitor. These connections may include wires, plugs, or connectors. Take note of the arrangement or take a picture to help with reinstallation.

- Remove mounting screws or clips : The ignitor is typically held in place by screws or clips. Remove these fasteners to release the part from its mounting bracket or housing. Keep track of the removed hardware for reassembly.

- Remove the old ignitor : Gently pull out or slide the old ignitor out of its position. Be cautious not to damage any surrounding components or wiring.

- Install the new ignitor : Take the new ignitor and carefully slide it into the same position as the old one. Ensure it aligns properly with the mounting bracket or housing.

- Reattach mounting screws or clips : Secure the new part in place by reattaching the mounting screws or clips. Tighten them securely but avoid over-tightening to prevent damage.

- Reconnect electrical connections : Reconnect the electrical connections to the new ignitor, ensuring they are properly secured and aligned. Double-check the arrangement with your notes or reference photo.

- Restore power and test : Turn the power back on at the circuit breaker or main electrical panel. Start the heating system and observe the ignition sequence to verify that the new ignitor is functioning correctly. Ensure the flame is stable and consistent.

How Proper Positioning Is Important for Optimal Performance

Proper positioning of the ignitor within the water heater is crucial for its optimal performance, reliable, and safe operation. Here are some guidelines for the placement of the part:

- Close proximity to the burner assembly : The hot surface ignitor should be positioned in close proximity to the burner assembly of the water heater. This allows for efficient heat transfer from the element to the fuel gas, promoting reliable ignition.

- Clearance from other components : Ensure that the ignitor has sufficient clearance from other components, such as gas lines, wiring, or insulation. This helps prevent any potential damage to the element or interference with its operation.

- Correct orientation : It should be positioned correctly according to the manufacturer’s instructions. Follow any specific guidelines regarding the orientation, alignment, or mounting to ensure proper functioning.

- Secure attachment : It should be securely attached or mounted in its designated location within the water heater. This prevents any movement or displacement that could affect its performance or compromise its safety.

- Adherence to manufacturer’s instructions : Always refer to the water heater’s instruction manual or the specific guidelines provided by the manufacturer for the recommended positioning and installation steps. Each water heater model and ignitor type may have specific requirements that need to be followed.

It is important to note that the positioning of the ignitor may vary depending on the specific design and configuration of the water heater.

Comparing Hot Surface Ignitors to Other Ignition Systems

Here’s a side-by-side comparison of hot surface ignitors, pilot lights, and piezo ignition, the most common ignition systems used in gas water heaters:

Hot Surface Ignitors: Advantages

- Hot surface ignitors (HSIs) do not require a continuously burning flame, resulting in reduced energy consumption and lower utility bills.

- They provide consistent ignition without the risk of pilot lights going out due to drafts or other factors, ensuring reliable operation and an uninterrupted hot water supply.

- HSIs often incorporate safety features such as flame sensors and safety shut-off mechanisms, enhancing safety by detecting and responding to flame failure or abnormal conditions .

- They eliminate the need for manual relighting, making operation more convenient for users.

- Although HSIs may have a higher upfront cost compared to pilot lights, long-term energy savings, and increased reliability can result in cost savings over the life of the appliance.

Hot Surface Ignitors: Disadvantages

- Hot surface ignitors rely on an electrical power supply, which means they require a power source and proper wiring connections during installation.

- While they are generally reliable, they may require occasional inspection and cleaning to ensure optimal performance.

Pilot Lights: Advantages

- Pilot lights are a traditional and straightforward ignition method, relying on a continuously burning flame.

- Pilot lights do not require an electrical power supply, making them suitable for situations where electricity is unavailable or unreliable.

- They have been used for many years and have a proven track record of functionality.

Pilot Lights: Disadvantages

- Pilot lights consume fuel continuously since the flame needs to burn at all times, resulting in higher energy consumption and increased utility costs.

- Pilot lights can go out due to drafts, interruptions in gas supply, or other factors, requiring manual relighting.

- They can pose safety risks if the flame goes out unnoticed, leading to the accumulation of unburned gas and potential hazards.

Piezo Ignition: Advantages

- Piezo ignition systems generate sparks using mechanical force, eliminating the need for an electrical power supply.

- Piezo ignition systems are relatively simple and do not require complex electrical connections or components.

- They produce sparks instantly, resulting in quick and reliable ignition.

Piezo Ignition: Disadvantages

- Like pilot lights, piezo ignition systems require a continuously burning flame to maintain ignition, leading to higher energy consumption and increased utility costs.

- These systems can be prone to failure or degradation over time, requiring repair or replacement.

- Piezo ignition systems generally lack built-in safety features, such as flame sensors or automatic shut-off mechanisms, making them potentially less safe compared to HSIs.

Hot surface ignitors have revolutionized the ignition process in water heaters, offering enhanced efficiency and reliability. With their ability to eliminate the need for pilot lights, HSIs improve energy consumption while ensuring consistent ignition.

Proper installation, regular maintenance, and adherence to safety regulations are vital for their optimal performance. As technology advances, we can anticipate further developments in ignition systems, optimizing water heater efficiency and delivering reliable hot water when we need it most.

If a hot surface ignitor is not glowing, it may be due to various factors. Common causes include issues with the power supply, a faulty or worn-out element, improper grounding, loose or damaged wiring, problems with the control board, or gas supply issues. To resolve the problem, check the power supply, inspect the ignitor for damage, ensure proper grounding, examine the wiring connections, consider control board troubleshooting, and verify the gas supply.

Hot surface ignitors are generally not interchangeable across different models or manufacturers. While there may be some cases where compatibility exists, it is important to use the specific model recommended by the manufacturer of your heating system. Hot surface ignitors vary in terms of their physical dimensions, electrical characteristics, and compatibility with the control system of the heating equipment. Using an incorrect or incompatible part can result in improper operation, potential damage to the equipment, and compromised safety.

Hot surface ignitors are typically not designed to be cleaned. They are made of delicate materials, such as silicon nitride or silicon carbide, which can be easily damaged or compromised by cleaning attempts. It’s best to avoid cleaning the element unless specifically mentioned in the manufacturer’s instructions.

Related Articles

When to Replace a Water Heater: Key Signs to Look Out For

Your water heater is one of those household appliances you probably don’t think about until something goes wrong. Yet, like any other appliance, they have a lifespan and will eventually…

The Importance of RV Water Heater Anode Rods: Keep Rust and Corrosion at Bay

Navigating the world of RV water heater maintenance can be both exciting and challenging, but there’s one essential component that often goes unnoticed until it’s too late: the anode rod. Discovering…

How to Replace a Water Heater Thermostat on the Electric Models: DIY Tips

Learn how to replace a water heater thermostat on the electric models fast and easy. See how does a thermostat work, explore the types, common problems, and how to test…

Similar Posts

Are Power Vent Water Heaters Better?

Investing in a high-performing water heater is a wise decision as it can help you save money on energy consumption and expensive services. Among the various types of water heating…

AO Smith Tankless Error Codes: Troubleshooting Guide

Learn about AO Smith tankless error codes for easy and inexpensive troubleshooting. The repair guide covers indoor, outdoor, condensing, non-condensing, and ultra-low NOx water heaters with on-demand technology. Use the…

Choosing the Right Hot Water Solution: Point-of-Use (POU) vs. Centralized Systems

When selecting the best hot water system for your home, understanding the differences between point-of-use (POU) vs. centralized systems is crucial. Each system offers distinct benefits and drawbacks, and the…

Protect Your Investment: Prevent Water Heater Corrosion With These Proven Tips

Water heater corrosion is a significant concern for homeowners and users of hot water systems. Corrosion refers to the gradual deterioration of metal components in a water heater due to…

Water Heater Sizing Guide: How to Select the Right Size

If you are shopping for a new electric or gas tank-type water heater, you should first get familiar with the water heater sizing guide. By getting the right tank size,…

Dealing with a Water Heater Gas Leak: Symptoms, Causes, and Solutions

Gas water heaters are a common appliance found in many homes and businesses that use natural gas or propane as a fuel source to heat water. While they are generally…

- My Account

- Sign in or Create an account

Currency Displayed in

- New Products

- Advanced Distributor Products

- BASO Gas Products

- BOSS Products

- Comfort Aire

- Crown Boiler

- Diversitech

- E Instruments

- Evergreen Motors

- Fieldpiece Instruments

- Flow Right Filter Box

- GeneralAire

- Harris Products

- Honeywell Genetron

- ICM Controls

- JB Industries

- Klein Tools

- Little Giant

- Mueller Streamline

- Sure Comfort

- Turbo Torch

- UEI Test Instruments

- Velocity Boiler

- Victor Technologies

- White Rodgers

- Yellow Jacket

- Mini-Split Systems

- Manufactured Housing

- Residential Unitary

- Air Conditioning Refrigeration Components

- Pumps & Parts

- System Components

- Valves & Controls

- Hydronics & Plumbing

- Zone Valves

- Blowers & Draft Inducers

- General Purpose Blowers

- OEM Replacement Draft Inducer Blowers

- Motor Accessories

- Compressors

- Refrigerant

- Accessories

- Acid Control

- Air Distribution (Grilles, Sheet Metal, Etc.)

- Brazing & Soldering Supplies

- Caulking & Sealants

- Cleaners & Chemicals

- Condensate Drain Supplies

- Condensate Pumps

- General Purpose Chemicals

- Hoses & Sprayers

- Installation & Maintenance Supplies

- Leak Detection

- Leak Sealant

- Lineset Flushes

- Electrical Installation & Maintenance Supplies

- Test Instruments

- Service Kits

- Leak Detectors

- Thermostats

- Indoor Air Quality (IAQ)

- Ventilation

- HVACR Parts

- Gas Heat Controls

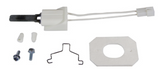

Trane KIT03033 Replacement Voyager Igniter

Related products.

Hover over image to zoom

Product Description

Specifications:

- Steady current: 4.25 Amps @ 115 VAC.

- Max. Current: 5 Amps @ 132VAC.

- Time to Temp (1800°F): < 17 seconds

Replaces: Trane KIT03033

Used In: Trane package models beginning with YCD15, YCD17 and YCD18

Icludes igniter, gasket, clip, mounting screws and installation instructions

Find Similar Products by Category

You recently viewed....

Quick Links

- Doofinder Search

- How To Optimize Your AC this Summer

- Our Company

- Customer Service

- Terms and Conditions

- PayPal Financing

Featured Brand

Follow us on

Copyright 2024 Climatedoctors . All Rights Reserved.

All prices are in USD .

Selected For Comparision

Compare Now

Click the button below to add the Trane KIT03033 Replacement Voyager Igniter to your wish list.

IGN00145 American Standard Trane Furnace Hot Surface Ignitor

$ 58.50

The IGN00145 American Standard, Trane furnace hot surface ignitor is a brand new OEM ignitor that comes in an Trane, American Standard OEM factory Service First box. The IGN00145 ignitor is a new, upgraded Trane furnace hot surface ignitor that replaces old part numbers: IGN00117 and IGN00104 as of November 2010.

Captcha * Refresh Captcha

Description

Additional information.

- The IGN00145 American Standard Trane Furnace Hot Surface Ignitor is a brand new OEM ignitor that comes in an Trane, American Standard OEM factory Service First box.

- The IGN00145 ignitor is a new, upgraded Trane furnace hot surface ignitor that replaces old part numbers: IGN00117 and IGN00104 as of November 2010.

- The mounting is the same as the IGN00117. The only difference is the white porcelin is round on the IGN00145.

- The IGN00117 ignitor had a rectangular white porcelain shape.

- The IGN00145 ignitor is a Silicon Nitride 80 volt ignitor just like the IGN00117.

- The ignitor comes in a kit with a mounting bracket.

Related products

51-23012-41 Rheem Ruud Furnace Blower Motor

HC43AE117 Bryant Carrier Furnace Blower Motor

0131F00022SP Goodman Furnace Blower Motor

51-23017-42 Rheem Ruud Furnace Blower Motor

- Tools & Home Improvement

- Building Supplies

- Furnace Parts & Accessories

Image Unavailable

- To view this video download Flash Player

Trane KIT03033 Ignitor Kit

Purchase options and add-ons, about this item.

- This is an O.E.M. authorized part

- Fits various Trane models

- OEM Part Number KIT03033

- This is a Trane replacement part

- Part Number KIT03033

- This is an O.E.M. part

- Genuine OEM replacement part

- Trane provides services that are widely used in the foodservice industry

- Use genuine OEM parts for safety reliability and performance

Buy it with

Customers also viewed these products

Looking for specific info?

Product description.

Trane KIT03033 Hot Surface Furnace Ignitor Kit is a genuine OEM (original equipment manufacturer) replacement part designed to fit a variety of Trane furnaces. This ignitor kit is compatible with hundreds of Trane Package Roof Top Units. The full kit includes an ignitor, clip, gasket and mounting screws. Use genuine OEM parts for safety, reliability and performance. Trane has been a pioneer in the climate control industry for over a century. With a variety of chillers, unitary systems, air handling systems, ductless products and terminal devices, Trane has any efficient product to meet your needs.

From the Manufacturer

KIT03033, KIT, IGNITOR. Trane Genuine OEM replacement part. Trane provides services that are widely used in the foodservice industry. Use genuine OEM parts for safety reliability and performance.

Product information

Technical details, additional information, warranty & support, customer reviews.

- 5 star 4 star 3 star 2 star 1 star 5 star 36% 41% 0% 0% 23% 36%

- 5 star 4 star 3 star 2 star 1 star 4 star 36% 41% 0% 0% 23% 41%

- 5 star 4 star 3 star 2 star 1 star 3 star 36% 41% 0% 0% 23% 0%

- 5 star 4 star 3 star 2 star 1 star 2 star 36% 41% 0% 0% 23% 0%

- 5 star 4 star 3 star 2 star 1 star 1 star 36% 41% 0% 0% 23% 23%

Customer Reviews, including Product Star Ratings help customers to learn more about the product and decide whether it is the right product for them.

To calculate the overall star rating and percentage breakdown by star, we don’t use a simple average. Instead, our system considers things like how recent a review is and if the reviewer bought the item on Amazon. It also analyzed reviews to verify trustworthiness.

- Sort reviews by Top reviews Most recent Top reviews

Top reviews from the United States

There was a problem filtering reviews right now. please try again later..

- Amazon Newsletter

- About Amazon

- Accessibility

- Sustainability

- Press Center

- Investor Relations

- Amazon Devices

- Amazon Science

- Sell on Amazon

- Sell apps on Amazon

- Supply to Amazon

- Protect & Build Your Brand

- Become an Affiliate

- Become a Delivery Driver

- Start a Package Delivery Business

- Advertise Your Products

- Self-Publish with Us

- Become an Amazon Hub Partner

- › See More Ways to Make Money

- Amazon Visa

- Amazon Store Card

- Amazon Secured Card

- Amazon Business Card

- Shop with Points

- Credit Card Marketplace

- Reload Your Balance

- Amazon Currency Converter

- Your Account

- Your Orders

- Shipping Rates & Policies

- Amazon Prime

- Returns & Replacements

- Manage Your Content and Devices

- Recalls and Product Safety Alerts

- Registry & Gift List

- Conditions of Use

- Privacy Notice

- Consumer Health Data Privacy Disclosure

- Your Ads Privacy Choices

Shopping Cart:

- Parts Counter: 38568 Webb Dr. Westland, MI 48185

Customer Login

If you are already registered, please log in.

Create your account and enjoy a new shopping experience.

Open M-F 8-5 EST

- Hot Surface Ignitor

Trane IGN00054USA Hot Surface Ignitor

Have Questions? Ask a Tech!

Genuine OEM Parts

Offering genuine parts for your specific brand.

In-House HVAC Techs

We help you diagnose, find, and install the part.

1-Year Warranty & Returns

Failed, or didn't need it? No hassle returns.

Expedited Delivery

Offering competitively-priced expedited shipping.

Write a Review

Frequently Bought Together

Video gallery, part info & specifications, trane ign00054usa replacement part.

NOTE: THIS PART IS NO LONGER AVAILABLE. IT HAS BEEN REPLACED BY PART # IGN00054

- (1) - Hot Surface Ignitor (IGN00054USA)

🔧 Note: To prevent early failure of your new hot surface ignitor, handle by the ceramic base only and avoid contact with the silicon surface. Oils from the skin interact with the material and can cause premature failure.

Replaces Old Trane Part Numbers

- IGN00054PRO

Other Part Numbers

IGNITOR; HOT SURFACE, 120V AT 3.5 AMP

Fits Trane and American Standard Models:

(Press ctrl + F to find model number below.)

Various. (Call 734-326-3900 with your model and serial number for more information.)

Related Products

Trane IGN00054 Hot Surface Ignitor

Trane ign00023 hot surface ignitor, trane ign00034 hot surface ignitor, trane ign00117 hot surface ignitor, trane ign00026 hot surface ignitor.

- Mark Forums Read

- Who's Online

- Thanks / Like Statistics

- Hottest Threads / Posts

- Contracting Business

- Advanced Search

- Ask Our Pros-Owner Assistance - NO DIY advice will be given.

- AOP Commercial HVAC and Refrigeration

- Hot surface ignitor

- Cookie Consent We use cookies to improve your website experience. To learn about our use of cookies and how you can manage your cookie settings, please see our Cookie Policy . By continuing to use the website, you consent to our use of cookies.

- Gain access to our free AOP (Ask a Professional) Section to get real answers for your questions. All this and much more is available to you absolutely free when you register ; for an account, so join our community today today! We suggest not registering using an AT&T, BellSouth, AOL or Yahoo email address. If you have any problems with the registration process or your account login, please contact support .

Thread: Hot surface ignitor

Thread tools.

- Show Printable Version

- View Profile

- View Forum Posts

- View Forum Threads

Trane voyager Have to install a new Hot surface ignitor every season Twice! last season The control module is good ,also new All ignitors properly insatlled, nice and tight Old ignitors are clean when removed. Is Trane modifying their ignitors

I'm not sure about this problem with Trane's equipment, but Ruud/Rheem had a batch several years ago with a similar problem. The solution was changing the position of the ignitor by 90º. What is the year model of your Voyager? You may also have a bad grounding contact. Just some suggestions off the top of my head...hope this helps or points you in the right direction.

Def. of insanity: doing the same thing over and over again expecting different results!!

i have starting having the same issue with the ignitors an trane charged me 80 bucks for 1. The ignitor is the smallest issue i have with the unit. Finally got them to fork over a kit for the inducer problems...

I change out more trane igniters then any other brands we work on. But its a norton made in some cases and I have used the trane models on Lochinvar boilers, in a pinch. They last on the boilers in most cases. But some tranes I too have to change every year. Which is not bad in the respect that I know I can get those two damn screws out without them breaking or cross threading. The igniters are like working with a bottle of nirtro. Look at it wrong and its all over. I'v had new ones that didnt even make the climp to the roof. Once I just tapped the side placing it in and that was enough to screw it up. I think it also may be the environment of the unit, as far as the combustion are intakeing crap and all. But do change a lot of tranes. You can find generic ones that will work and are cheaper. 20 degrees out side, wind blowing, cant feel the fingers and trying not to hit the sides while sliding the ingniter in place and night time with a stupid flash light that lights everything up,except what I need to see. GOOOOOD times. When its all said and done I go home sit down and think, Damn that was fun. I love my job. Redfive.

Originally Posted by redfive I change out more trane igniters then any other brands we work on. But its a norton made in some cases and I have used the trane models on Lochinvar boilers, in a pinch. They last on the boilers in most cases. But some tranes I too have to change every year. Which is not bad in the respect that I know I can get those two damn screws out without them breaking or cross threading. The igniters are like working with a bottle of nirtro. Look at it wrong and its all over. I'v had new ones that didnt even make the climp to the roof. Once I just tapped the side placing it in and that was enough to screw it up. I think it also may be the environment of the unit, as far as the combustion are intakeing crap and all. But do change a lot of tranes. You can find generic ones that will work and are cheaper. 20 degrees out side, wind blowing, cant feel the fingers and trying not to hit the sides while sliding the ingniter in place and night time with a stupid flash light that lights everything up,except what I need to see. GOOOOOD times. When its all said and done I go home sit down and think, Damn that was fun. I love my job. Redfive. Ive found my mini impact is best for them screws, but not a cure all. If you have a unit that the ignitiors are failing every year, remove the draft inducer and clean the screen behind it. actually i am just grabbing straws on what may be the issue...done EVER set the ignitors down. Even though u may not have damaged it you did just pick up dirt and yuck that sits in the compartment.

why are the HSI failing? broken? high resistance?, have you check the voltage going to the ignitor?

Years ago when rheem first went to the hot surface ignitors, I replaced one two times in one winter. I called the factory rep. and he told me to be sure not to touch it with your bare fingers because the small amount of oil on your fingers or hands would cause it to burn out prematurely. I took his advice and never had to change it again, coincidence or not.

Trane needs to come up with a new plan because the one they have does not work. Same with there comb. blowers.

- Private Messages

- Subscriptions

- Search Forums

- Forums Home

- The #1 question asked by NEW MEMBERS. Please read this...

- Questions About Becoming A Professional Member? Step Inside...

- SITE Software Issues? Post Them Here

- RULES for AOP - Owner Assistance and Contractors

- AOP Residential HVAC and Refrigeration (Beenthere Zone)

- General Discussion

- Job Wanted/Needed Discussion

- Industry and Forum News

- Webinars and Virtual Events

- Tech to Tech Chat - Residential

- Tech to Tech Chat - Commercial

- Refrigeration & Ice Making

- Members Inventions **NEW

- Test & Balancing Forum NEW

- Control Sales Forum

- Professional Controls Forum

- Control Jobs Forum

- Chillers Open Forum

- Energy Efficiency and Building Performance Discussion NEW

- Commercial Food Service Equipment

- Residential Geo Thermal / Water Source

- Commercial Geo Thermal / Water Source

- Indoor Air Quality

- Tools & Test Equipment

- Food and Grill Forum

- "Wall of Pride" - Pictures

- "Wall of Shame" - Pictures

- How To Become a Pro and Rules For Pro Members

- Pro's Forum: General Discussion

- Charlie's Corner (Icemeister)

- HVAC Basics **NEW

- Pro Forum: Refrigerants and EPA regulations **NEW

- Pro's Forum: Business & Marketing

- Pro Forum: Residential Refrigeration and Appliances **NEW

- Pro's Forum: Sales

- Pro Forum: Equipment Recalls and Bulletins **NEW

- Pro's Forum: Residential

- Pro's Forum: Commercial

- Pro's Forum: Geo Thermal / Water Source

- Pro's Forum: Refrigeration & Ice

- Pro's Forum: Chillers

- Pro's Forum: Oil Burners

- Pro's Forum: Hydronics/Boilers

- Pro's Forum: Building Science Discussions

- Pro's Forum: Training and Education

- Pro's Forum: Instructors Forum NEW

- Pro's Forum: Tips 'n Tricks of the Trade

- Pro's Forum:The Gun Enthusiast

- Frequently Asked Questions About Submissions

- Manufacturers' Technical Information

- Articles Authored by Others

- Self-Authored Articles

- Submit Quiz Questions

- About the Suggestion Box

- Voice Your Opinions

- Share Ideas

- Report Problems

- Educational, Training & Reference Information

- Manufacturer's Technical Information Links

- Quiz Questions

- Open Forum Discussion

- Split Systems, Package Units, Furnaces

- Geothermal / Water Source Heat Pumps

- Specialty Systems

- Boilers Hydronic, Steam

- Accessories Humidifiers, Air Cleaners, HRUs, Fans, Filters, etc

- Components Coils, Heaters, Motors, etc.

- Compressors

- Oil Burners

- Systems - General

- Accessories Pumps, Cooling Towers, Evap Condensers, etc

- Components Valves, Motors, Condensers, Evaporators, etc

- Refrigeration Systems

- Evaporators, Condensers, Etc.

- Valves, Regulators, Filters, Etc.

- Walk-Ins, Cold Storage

- Food Service Equipment, Display Cases

- Supermarket Cases & Compressor Systems

- Ice Machines

- Controls, Motors, Etc

- HVAC Load Calc Software

- Refrigeration Load Calc Software

- HVACR Software & Online Training

- HVACR Calculators & Apps

- Formulas and Calculations

- In Memoriam

- Licensing, Laws, Codes and Certification

- Jokes, Quotations, Humor, Wisdom Pills

- Practice, Testing Area

- Plumbing Forum Rules

- Plumbing General Open Forum

- Pro's Forum: Plumbing Discussion

- Electrical Forum Rules

- Open Discussion Electrical

- Photovoltaic

- New Products

- Bonding & Grounding

- Motors & Motor Controls

- Test & Measurement

- Tools & Equipment

- Code Violations

- Pro's Forum: Power Quality

- Pro's Forum: Calculations & Electrical Theory

- Pro's Forum: Electrical Business & Marketing

- Pro's Forum: Estimating

- Job Postings

vBulletin Message

The following errors occurred with your submission, quick reply, register now.

Please enter the name by which you would like to log-in and be known on this site.

- Confirm Password:

Please enter a password for your user account. Note that passwords are case-sensitive.

- Email Address:

Please enter a valid email address for yourself.

- HVAC/R Contractor

- HVAC/R Technician/Installer

- HVAC/R Wholesaler/Distributor

- HVAC/R Manufacturer

- Manufacturer Rep

- HVAC/R Consultant

- HVAC/R Engineer

- Facilities manager/Mechanical Engineer

- Homeowner or Building/Equipment Owner (We welcome homeowners and Building owners. Help us customize your experience) Please post in the AOP Section

- Residential HVAC

- Light Commercial HVAC (up to 25 tons)

- Commercial HVAC (over 25 tons)

- Refrigeration

- Hydronic Heating

- Building Automation/Controls

Posting Permissions

- You may post new threads

- You may post replies

- You may not post attachments

- You may not edit your posts

- BB code is On

- Smilies are On

- [IMG] code is On

- [VIDEO] code is On

- HTML code is Off

Forum Rules

- HVAC-Talk.com

© VerticalScope Inc. All Rights Reserved.

IMAGES

VIDEO

COMMENTS

Hot Surface Ignitors (HSI) are used on Voyager II/III staged gas heat and modulating gas heat. They perform 2 functions: -Ignition source to light the burner. -Flame proving. Reasons for failure: Moisture or oils from hands during handling can cause failure when the HSI is energized. HSI are constructed from recrystallized silicon carbide and ...

Just curious what everyone does as far as replacement for hot surface igniters. Usually I try to replace them when they get around 100-110 ohms. ... normal ohms of a Trane 231T RTU igniter is 40 to 90 ohms, or 4.25 to 4.75 amps. ... like it better, been in residential 20 yrs an Im in the charlotte metro, im having voyager issues now , suspect ...

Trane Voyager 2 No Heat Installed New Ignition board and carefully installed correct,new hot surface igniter Combustion Motor good , both speeds, can smell gas, valve OK No Flame, checked wires,OK 82 Volts AC to H.S.I. Jack Tech ordered new 208 volt by 120 Volt transformer . Flame check pins 1Volt= 1uA. 2 to 8 Volts DC should be present AFTER flame is established?

A hot surface ignitor will usually read somewhere around 40-100 ohms, depending on the type. Sometimes, it will read up to 200 ohms or more. But if it reads much higher than that, there's a good chance that it's going bad (or already is bad). ... Hot surface ignitors are in most newer furnaces on the market today. They are made of a ceramic ...

voyager ignition problem. Working on a trane voyager ycd180. Unit will not ignite. Combustion blower comes on, hsi energizes, I can smell gas through outlet of heat exchanger but doesn't try to light. I understand how the gas valve works, w/negative pressure and all. When the combustion fan starts the outlet pressure of gv is -2.62" wg.

Hot Surface Igniter Fact Sheet

when performing work such as hot work, electrical, fall protection, lockout/tagout, refrigerant handling, etc. Where local regulations are more stringent than these policies, those regulations supersede these policies. • Non-Trane personnel should always follow local regulations. WARNING R-454B Flammable A2L Refrigerant!

I have a Trane TUD080C936J0 gas furnace/ac. The furnace starts up via a hot surface ignitor. ... This one has about 40-50 ohms resistance, but the furnace still flashes "check hot surface ignitor. I've plugged my multimeter into the plug that goes to the ignitor and when the thermostat calls for heat it spikes for a moment (I typically see 500 ...

Note: To prevent early failure of your new hot surface ignitor, handle by the ceramic base only and avoid contact with the silicon surface. Oils from the skin interact with the material and can cause premature failure. Replaces Old Trane Part Numbers. IGN00117; Other Part Numbers. Service First, 3L1, 1347 1347L359, D343692

Remove it from the system and disconnect any wiring connections. Touch the multimeter probes to the two electrical terminals of the ignitor, ensuring a secure connection. A good silicon nitride hot surface ignitor should have a resistance reading between 30 to 75 ohms (depending on the manufacturer and model).

WARNING: Information in this article is intended for use by individuals possessing adequate backgrounds of electrical and mechanical experience and who comply with all federal, state, and local laws, rules, orders, or regulations related to the installation, service, or repair of a heating or central air conditioning product.

Normal, call for heat (¾ second on, ¼ second off) 1 Flash. Loss of Communication . 2 Flashes. System Lockout: Failed to detect or sustain a flame. (failure to ignite, no spark, low/ no gas pressure, etc.) 3 Flashes. Pressure switch problem detected. (no vent air flow, bad CBM, closed at an initial call for heat). Auto reset.

† The hot surface ignitor is a gas ignition device which doubles as a safety device utilizing a continuous test to prove the fl ame. Weather Tight Top and C abinet † Voyager units incorporate the Trane-Tite-Top (T 3). Each part of the top (three pieces) overlaps in such a way that water cannot leak into the unit. These overlapped

Trane gas furnace question. I was working on a Trane natural gas high efficiency furnace today and when I tested the hot surface ignitor for resistance it had only 16 ohms across it. I did unplug it (isolated it) for the rest of the furnace before I tested it. MOST ignitors that I test have around 60 ohms at best (even new ones).

Trane B144676P01 Hot Surface 41-410 HSI Igniter $18.25. Add To Cart. Add to Compare. Add to Wishlist. Goodman 0230K00000S Replacement Igniter $41.60. Add To Cart. Add to Compare. Add to Wishlist. Trane KIT03033 Replacement Voyager Igniter. Hover over image to zoom. $32.51. SKU: IGN5 Availability: Usually ships within 24 hours ...

The IGN00145 ignitor is a new, upgraded Trane furnace hot surface ignitor that replaces old part numbers: IGN00117 and IGN00104 as of November 2010. The mounting is the same as the IGN00117. The only difference is the white porcelin is round on the IGN00145. The IGN00117 ignitor had a rectangular white porcelain shape.

Product Description. Trane KIT03033 Hot Surface Furnace Ignitor Kit is a genuine OEM (original equipment manufacturer) replacement part designed to fit a variety of Trane furnaces. This ignitor kit is compatible with hundreds of Trane Package Roof Top Units. The full kit includes an ignitor, clip, gasket and mounting screws.

Trane Parts - Furnace & AC. It's hard to stop a Trane. But on the off chance your Trane unit needs parts or maintenance, it's easy to fix! As a leading brand in heating, ventilation, and air conditioning, Trane is known for their known for their reliability and high quality. Using high-quality OEM Trane HVAC parts is a great way to keep units ...

IGN00054. IGN00054PRO. Other Part Numbers. IGNITOR; HOT SURFACE, 120V AT 3.5 AMP. Fits Trane and American Standard Models: (Press ctrl + F to find model number below.) Various. (Call 734-326-3900 with your model and serial number for more information.) Trust Technical Hot & Cold for the right OEM replacement part.

We are so excited to announce that our XV20i Variable Speed Heat Pump with Trane Link has been selected as a Good Housekeeping 2023 Home Renovation Award winner! After months of rigorous...

Trane voyager Have to install a new Hot surface ignitor every season Twice! last season The control module is good ,also new All ignitors properly insatlled, nice and tight Old ignitors are clean when removed. Is Trane modifying their ignitors ... Thread: Hot surface ignitor. Thread Tools. Show Printable Version; 12-16-2004, 10:51 PM #1 ...

with Voyager RSS profiles (pure N 2) • At tropopause HASI T ~ 1K colder, but assuming 98.5% N 2+1.5% CH 4 -> 70.5 K [Lellouch el al. 1989] • Temperature variations in lower stratosphere coherent with linear, free propagating gravity waves as derived from Voyager RSS [Friedson, 1994] [Flasar et al 2005 Science] • Presence of layers also

The moment you've been waiting for. The first competition - battle of the electricians - airs tonight in the Elite Trades Championship Series at 8 p.m. ET on CBS Sports Network. Of course, we are...